Read this article in Français Deutsch Italiano Português Español

Road building robotics firm releases third-gen rebar-tying machine

10 September 2024

Advanced Construction Robotics (ACR) – a global US-based manufacturer of autonomous robotic equipment – said the third generation of its rebar-tying robot, TyBOT, is available to purchase and deliverable by 2025’s first quarter.

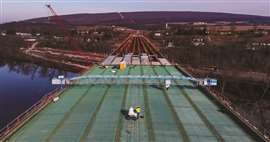

Advanced Construction Robotics’ (ACR) TyBOT working a bridge job in Pennsylvania, US (Image: ACR)

Advanced Construction Robotics’ (ACR) TyBOT working a bridge job in Pennsylvania, US (Image: ACR)

TyBOT 3.0 was previously only available to customers via ACR’s RaaS (robot as a service) model.

TyBOT – called the ‘rebar-tying robot’ – was the firm’s first product upon its launch nearly six years ago.

Designed for the roadbuilding and bridge construction segments, TyBot specialises in tying rebar; it works at speeds in excess of 1,200 ties-per-hour using 15-lbs (6.8kg) of wire spool and can tie epoxy coated bar and black bar. It can manage these tasks uses sensors and without pre-mapping, calibration or BIM input.

The third iteration comes standard at a 67-ft width, but a fully configured expansion can reach 117 ft, said ACR.

The company said customers also receive comprehensive training by ACR to ensure customers can “confidently mobilise, configure, supervise, and maintain TyBOT from day one.”

ACR’s also offers a “Service Platform Subscription” which gives end-users access to a live data portal with insight into their rebar installation operations as well as access to software features from ACR’s engineering team.

“TyBOT 3.0 also has optional accessories to further expand its cost-saving capabilities, including multiple modes of travel for non-bridge projects and a carry function add-on to transport materials efficiently and safely to working crew members,” added ACR.

Danielle Proctor, president and CEO of ACR, noted the machine’s growing presence since its launch less than one decade ago.,

“With over 65 field deployments nationwide, TyBOT has proven that it provides customers at least 25% savings in their installation operations and is quickly becoming an accepted tool of the trade by rodbusters,” she said. “We’ve seen a tremendous increase in demand for TyBOT as well as our second product, IronBOT, the rebar-placing robot.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM