Read this article in Français Deutsch Italiano Português Español

Evaluating compressed hydrogen’s role in maritime decarbonization

27 June 2025

Norway’s Hexagon Group is known for the alternative fuel systems it provides for commercial vehicles, which include high-pressure composite tanks for onboard fuel storage. In 2021, the company established a new division, Hexagon Purus Maritime.

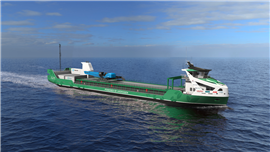

In 2021, Hexagon Purus joined the ZeroCoaster project study to explore hydrogen in maritime applications. (Image: Hexagon Purus)

In 2021, Hexagon Purus joined the ZeroCoaster project study to explore hydrogen in maritime applications. (Image: Hexagon Purus)

“The strategy was to employ engineers with a maritime background and adapt the technology from the rest of the Hexagon Group to shipping applications,” said Robert Haugen, managing director of Hexagon Purus Maritime.

Haugen worked in the maritime sector before joining Hexagon, including an operational stint working with a large South American fishing vessel. He addressed the use of compressed hydrogen for maritime vessels during a recent Mission Hydrogen webinar.

“When I took the position at Hexagon, my motivation was to continue to work for positive impact on the environment through making Hexagon technology available also in the maritime segment,” he said.

Maritime Vessel Variety

According to Haugen, addressing why more maritime vessels do not have zero-emission solutions like compressed hydrogen must begin with defining what the maritime vessel is, as there is great variety among commercial boats and ships. They include everything from large cargo vessels to fast ferries to leisure craft to barges.

“All these vessels have very different shapes, energy consumption and purposes,” he said. “They follow different rules and regulations. They carry different types of cargo. They earn their value in different ways. Some of the vessels move in limited local areas, while others cross large oceans.”

Haugen added, “The complexity and differences between each vessel and vessel type need to be understood when developing hydrogen fuel systems. For example, a fast ferry will have very different needs than a bulk carrier. Where does the storage of fuel go? What will be the safety zones? Who will operate and maintain the system?”

Adding an additional wrinkle is the fact that there are no specific instructions for the use of compressed hydrogen in most ship types.

“Each project mode goes through what they call an alternative ship design, through the IMO 1455 regulation, where the task is to prove through safety analysis that the compressed hydrogen fuel system is as safe or safer than existing fuel systems,” Haugen said.

Understanding Duty Cycles

Ship type is not the only source of variety. Maritime vessels operate across a spectrum of duty cycles that must be considered when engineering for compressed hydrogen.

Hexagon Purus Maritime’s offices in Ålesund, Norway. (Photo: Hexagon Purus)

Hexagon Purus Maritime’s offices in Ålesund, Norway. (Photo: Hexagon Purus)

“Compressed hydrogen fuel takes a lot of space onboard — much more than conventional diesel,” Haugen said. He added that for most diesel vessels, the fuel is stored at the bottom of the hull, which acts as ballast and stabilizes the ship.

“You can bring fuel to last for months in some cases,” he said. “So, the operational pattern today is, fuel the vessel and forget about it for a long time.”

That need not be the case, however, Haugen said, as there are many vessels that do not operate for extended periods without the ability to regularly refuel.

“Some vessels move along the coast or up and down a river,” he said. “Many vessels spend a lot of time unloading or loading cargo. These vessels are well-suited for compressed hydrogen.”

Nonetheless, adopting compressed hydrogen requires a mindset change among maritime vessel owners and operators.

“We have to consider that many of the vessel owners have done it the same way in terms of fueling for generations,” Haugen said.

Nonetheless, success stories do exist.

“We have two ferries operating only 50 minutes from our office on the west coast of Norway,” he said. “The crossing takes only 23 minutes. The two previous ferries used 80 L of diesel to cross the fjord. Now, two fully electric ferries are doing the same work using 480 kWh to cross the fjord.”

According to Haugen, the ferries recharge at each end of their journey in only six minutes using a 6 MW charger.

The ferry could experience extended range, however, if it operated on compressed hydrogen. Haugen said that it would be able to operate all day — making 44 crossings — without refueling, based on a fuel tank roughly the size of a 40-ft. container.

“This ferry does not operate during the middle of the night — a perfect time for refueling,” he said. “This is an example of how we need to rethink operational patterns to facilitate zero-emission operation.”

Energy Efficiency Focus

According to Haugen, designing for compressed hydrogen means evaluating energy consumption aboard the vessel. Fortunately, the industry has taken great strides in promoting energy efficiency.

“The nozzle on the propeller, hull optimization, peak shaving with batteries and heat recovery are all major energy efficiency improvements you will find on vessels today,” Haugen said. “This is good news for all new zero-emission fuels where energy density is lower than traditional fuels. A kilogram of hydrogen takes you [further] if energy efficiency is optimized.”

Considering All Solutions

When evaluating whether compressed hydrogen is appropriate for a certain vessel, Haugen said Hexagon is mindful of the entire zero-emission power spectrum.

High-pressure fuel cylinders inside Hexagon Purus Maritime’s offices. (Photo: Hexagon Purus)

High-pressure fuel cylinders inside Hexagon Purus Maritime’s offices. (Photo: Hexagon Purus)

“If it is possible, from a vessel and operational profile point of view — including power grid availability — we always suggest full battery operation,” he said. “This is the most efficient way of using the energy.”

Nonetheless, Haugen noted that most vessels are too large for a battery-electric (BE) solution to be feasible, and for many, recharging effectively is a concern.

“When battery [power] on its own does not make it, compressed hydrogen comes in,” he said, adding that after BE power, compressed hydrogen is the most efficient zero-emission power source.

Haugen listed a variety of vessels for which compressed hydrogen is often a good solution. These include passenger vessels, ferries and fast ferries, roll-on-roll-off vessels, inland waterway barges, service and supply vessels, fish carriers, cargo vessels and “all vessels with predictable coastal operation and a maximum of a couple of days operation between filling with fuel.”

Ship complexity remains a limiting factor, he said. Vessels with more significant energy needs can use other hydrogen fuels, such as liquefied hydrogen.

“You lose more of the energy with liquid hydrogen, but it takes less space in larger quantities,” Haugen said.

No Silver Bullet

Regardless of the solution, Haugen said zero-emission maritime power solutions are urgently needed.

“We need to be in dialogue with ship owners, designers and yards to educate them in what is possible and what is not,” he said. “We need to understand the differences in maritime vessels and their different needs and limitations.”

Haugen added that alternative fuels such as compressed hydrogen will serve a unique purpose in the maritime sector.

“There will be no one silver bullet fuel for the future in the same way that diesel could serve the complete market up until now,” he said. “Green hydrogen will play an important role.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM