Read this article in 中文 Français Deutsch Italiano Português Español

H2-focused and hybrid-electric: EVS Hydrogen multi-fuel engines promise flexibility, future-proofing

17 March 2025

While electrification would seem to be the tool of choice in achieving net zero emissions, hydrogen (H2) holds significant promise. Already being used in fuel cell electric vehicles (FCEV), many engine makers are exploring H2 as a fuel for internal combustion (IC) engines.

One such company is EVS Hydrogen. The engine manufacturer based in the Bavarian municipality of Untergriesbach, Germany, plans to showcase its hydrogen engines at Bauma 2025.

“We firmly believe that hydrogen is the future of energy, and it’s essential to prepare for its adoption today,” said Günther Kneidinger, CEO of EVS Hydrogen.

Hydrogen-Ready Multi-fuel

Hydrogen combustion was the primary goal when EVS Hydrogen designed its engines, Kneidinger said. Spanning a power range of 10 to 100 kW, they are nonetheless engineered to support multiple fuels.

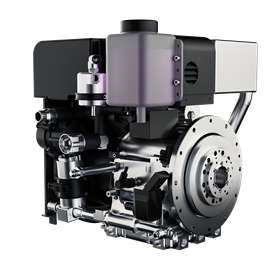

An EVS Hydrogen multi-fuel engine. (Photo: EVS Hydrogen)

An EVS Hydrogen multi-fuel engine. (Photo: EVS Hydrogen)

“Multi-fuel technology means that a single engine system can utilize multiple types of fuels — both liquid and gaseous,” Kneidinger said. He added that in addition to hydrogen, the company’s engines can run on biogas, natural gas, methane — even kerosene and gasoline.

According to Kneidinger, uncertainty about hydrogen fuel led the company to explore multi-fuel technology.

“We saw people, especially in Europe — they were not certain when hydrogen will come, or will it come, or will it not come,” he said. “We said in our opinion, yes, definitely — hydrogen is the future. But the people were not ready to start with hydrogen.”

EVS Hydrogen chose to examine how the engine could use fuels that are important to customers now. The ignition profile of hydrogen, which Kneidinger called “the perfect fuel,” allowed the company to adapt its engines to also operate with slower-burning spark-ignited fuels.

He said this approach is beneficial for OEMs that want their equipment to be hydrogen-ready or have concerns about the price and availability of H2 in the future, both of which are challenges in the market today.

“[Customers] are not locked into one fuel type and have the flexibility to transition to hydrogen when ready,” Kneidinger said. “Currently, we see that most customers prefer to start with methanol or ethanol.”

Changing from one fuel type to another is not something end users can do on the fly — they can’t use methanol one day and hydrogen the next, for example. However, it is relatively easy at the OEM level or from the EVS Hydrogen factory.

“The only important thing for us is to know from the beginning is do [customers] want to get the multi-fuel technology or not,” Kneidinger said. “If they would like to get it, then there are different tubes — how the gaseous or liquid fuel gets into the engine — [and] our electronic board to realize which kind of fuel is [being used].”

For OEMs that want to change which type of fuel is used on a particular machine, perhaps as a running change, Kneidinger said there are only a “few screws they have to change by themselves. That is an easy job for them. Then they can change between the different fuels.”

Advantages Over Fuel Cells

Kneidinger noted that EVS Hydrogen engines are not in competition with hydrogen fuel cells, saying that each technology has its place. However, the purity of fuel required for use in fuel cells can be a challenge for some equipment in certain environments.

In a June 2024 Power Progress story, Jamie King of the Alberta (Canada) Motor Transport Association (AMTA), which has been doing research into the feasibility of hydrogen fuel, said that fuel-cell-grade hydrogen requires a purity of six nines, i.e., it must be 99.999999 percent pure.

In extremely cold temperatures like those in Canada, condensation can accumulate in fueling lines, which can dilute the hydrogen purity.

Kneidinger said that hydrogen fuel purity is not a concern in hydrogen IC engines, and that water in the fuel has no effect on the ability of EVS Hydrogen engines to perform.

“We have a lot of RFQs now from markets where it is really hot or really cold,” he said. “People from Africa who tested all the fuel cells, they say above 40 degrees [Celsius], it’s a little bit tricky with the fuel cell. And with a lot of dust, it’s also tricky for the fuel cell. If the humidity is too high, it’s a little bit tricky for the fuel cell. And for us, it doesn’t matter if there are water crystals inside [the fuel] or not.”

Part of the reason for this flexibility is the multi-fuel technology. “We can mix different gases to burn — hydrogen and biomethane, for example,” Kneidinger said. “That’s for us not a problem.”

Hybrid-Electric Technology

EVS Hydrogen engines have been designed for a wide range of off-highway applications due in part to a unique advantage: they are hybrid-electric.

“On the shaft, we have a generator,” Kneidinger said, “and with this generator, we produce all the electrical power. That means if somebody is running our combustion engine, he can also then put electrical energy into a battery or an APU (auxiliary power unit). Then he can drive electrically if he wants.”

The power generation capability opens the engine to a wider range of applications, Kneidinger said, including as a backup generator and range extender.

He added that the hybridization allows EVS Hydrogen engines to more efficiently address different load profiles across different applications.

“For example, the load profile of a mini excavator differs significantly from that of a compressor,” Kneidinger said. “Thanks to hybridization, we can adjust power output more precisely, providing greater flexibility and efficiency for various applications.”

According to Kneidinger, inquiries that EVS Hydrogen is fielding regarding its engines have indicated to him that the company is on the right track.

“We have developed a highly versatile product with strong international market potential,” he said. “The next steps involve expanding our internal production capacities and building additional manufacturing partnerships to prepare for future growth.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM