Read this article in 中文 Français Deutsch Italiano Português Español

Deutz joins H2 off-highway IC engine project

26 November 2024

PoWer project team members (Photo: Mahle)

PoWer project team members (Photo: Mahle)

German engine OEM Deutz has joined a consortium which is planning to develop hydrogen internal combustion engines for off-highway applications.

A key objective of the group will be to develop hydrogen-based drive concepts for construction and agriculture.

The ‘PoWer’ project will be led by Mahle, with other partners including Deutz, Purem by Eberspaecher, Claas, Liebherr, Nagel, Umicore, NGK and Castrol.

Technical institutes taking part include Karlsruhe Institute of Technology, Braunschweig University of Technology and the German Aerospace Centre.

Set to run for three years, the project is backed by €5.1 million in funding from the German Federal Ministry for Economic Affairs and Climate Protection. Product standards authority TÜV Rheinland is also providing support.

Total funding amount for the project was not disclosed.

The consortium will look to leverage ‘the inherent properties of hydrogen [internal combustion] engines’, including fuel efficiency, robustness and low untreated emissions, all qualities which make H2 IC engines ideal for construction and agriculture.

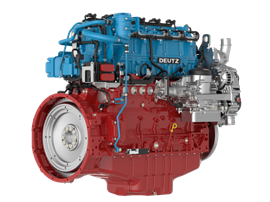

Deutz TCG 7.8 H2 engine (Photo: Deutz)

Deutz TCG 7.8 H2 engine (Photo: Deutz)

“At Deutz, we have already developed and unveiled a production-ready hydrogen engine – the TCG 7.8 H2,” said Dr. Paul Grzeschik, head of Design and Preliminary Development at Deutz.

“So we are delighted to be able to contribute our expertise to this joint project and work with strong partners in driving forward the development of hydrogen engines for the off-highway sector. Each project participant, whether from research or industry, is a proven expert in their field.

The intensive collaboration will allow us to utilize the potential for innovation for the transport sector and to significantly improve the technologies.”

The partners will use vehicle concept studies and analysis of fleet and infrastructure systems to demonstrate and evaluate off-highway applications. In addition, they will look to develop exhaust aftertreatment concepts for testing.

Deutz noted that by investigating how hydrogen affects materials, together with wear and friction characteristics, and by validating these properties in a running engine, all of the ‘building blocks’ will be put in place to meet engine robustness requirements – taking into account future NRMM emission standards.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM