GE marks first GT26 HE upgrade implementation, adds orders

20 July 2021

New orders for the upgrade in Argentina, Singapore

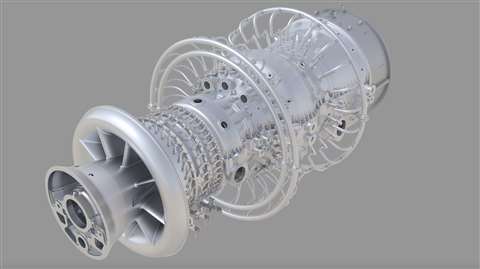

GE said it has completed the first implementation of its GT26 HE, the first high efficiency (HE) upgrade for the GT26 fleet, at Uniper’s Enfield Power Station in north London.

The upgrade was installed to improve the performance and extend the maintenance interval of the combined cycle plant.

A specifically engineered instrumentation network collected data from selected components and systems of the gas turbine—compressor, combustor, turbine and cooling systems during the first implementation campaign. An extensive test campaign conducted with over 2000 sensors providing data to GE’s engineering team to confirm safe and reliable operation. Operability, combustion, aeromechanics and key engine parameters were all within GE´s engineering acceptance criteria and the unit was successfully released for commercial operation.

GE’s GT26 HE upgrade test results showed key performance benefits, the company said:

Higher efficiency for combined-cycle power plants:

Up to 2% points baseload increased efficiency, translating to as much as US$4 million in fuel savings annually per unit.

Up to 1% point increased efficiency in part load, yielding up to US$1 million in fuel savings a year per unit

Increased plant output of up to 25 MW per unit

Extended inspection intervals up to 32 000 hours, reducing long-term maintenance costs.

GE marks success for first GT26 HE upgrade implementation, adds new orders.

GE marks success for first GT26 HE upgrade implementation, adds new orders.

“GE has invested significantly in the development of this upgrade. We are excited that the GT26 gas turbine at Uniper’s Enfield site is the world’s first GT26 unit equipped with the HE upgrade to achieve H-class performance levels approaching 60% combined cycle efficiency, demonstrating the significant technological investment GE has made in this upgrade” said Amit Kulkarni, head of Product Management for Heavy Duty Gas Turbines, GE Gas Power. “With the world shifting towards a lower carbon future, improving energy efficiency while increasing power output is a key way to generate more energy per unit of fuel with lower carbon emissions. This upgrade for a key Uniper facility, in addition to the cooperation agreement to decarbonize Uniper’s gas-fired power plants and storage facilities with GE technology, will enhance Uniper’s leading efforts to reduce the carbon footprint of their generation fleet. I’d expect this announcement will bring a positive disruptive influence in the power generation industry.”

New orders

GE also announced new orders for the upgrade secured from Enel Argentina’s Central Dock Sud and Keppel Merlimau Cogen Pte Ltd (KMC), respectively in Argentina and in Singapore.

Enel Argentina’s S.A. subsidiary Central Dock Sud S.A. today to have selected GE’s GT26 HE upgrade solution to increase power output, efficiency and maintenance intervals as well as extend the lifetime of its 755 MW Dock Sud Power Station located in Buenos Aires, commercially operational since 2001. With the installation of the HE Upgrade on two GT26 units within the end of next year, the plant is expected to inject over 100 MW into the grid. The HE upgrade has been engineered to maintain the dual fuel capability (diesel backup fuel in winter in case of natural gas shortage) and to allow for full retirement of the high-fogging system securing an additional 45 MW during summer, resulting in substantial cost savings.

Keppel Merlimau Cogen Pte Ltd (KMC) has selected the GT26 HE platform, for its combined cycle 1300 MW power plant in Jurong Island, Singapore. First in Singapore, KMC chose the advanced technology to upgrade its GT26 unit from F-class into H-class space. The upgrade that includes additive manufactured parts, aerodynamics innovation, and material science and combustion dynamics will help increase efficiency and fuel savings leading to lower carbon footprint. GT26 HE is expected to be installed in the second half of 2022.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM