GE plans aeroderivative investment

25 August 2022

GE announced a decision to invest up to $5 million over the next two years to add a second manufacturing location for GE’s TM 2500 and LM2500Xpress aeroderivative units for the Americas region in its existing Global Technology Center in Greenville, South Carolina, USA.

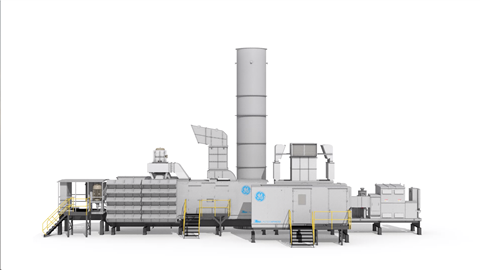

GE has announced plans for a $5 million investment at its Global Gas Turbine Technology Center in Greenville, South Carolina, (Photo: GE)

GE has announced plans for a $5 million investment at its Global Gas Turbine Technology Center in Greenville, South Carolina, (Photo: GE)

The new manufacturing hub will complement the current GE manufacturing site in Veresegyhaz, Hungary, the company said. GE said the move underscores its commitment to its highly flexible and mobile aeroderivative gas turbine technology, which can be used to help manage power shortages, stabilize the grid and support renewables growth.

GE’s Global Technology Center in Greenville will significantly increase its manufacturing capability to support deliveries in the Americans region, but also the global aeroderivative growth. According to a study by Global Market Insights, the global aeroderivative turbine segment is set to exceed $2.5 billion by 2025, demonstrating that the agile aeroderivative turbine technology is recognized for its compact size, lighter weight, quick start capability and operational flexibility. With quick start times, aeroderivative turbines are considered a crucial component for renewables balancing in grid systems. Aeroderivative turbines can start and stop daily and quickly, further enhancing their suitability to support renewable energy generation and grid balancing.

“With the increasing penetration of renewable energy, operational flexibility is key, and our aeroderivative turbines are engineered to provide reliable stable power to balance fluctuating renewable resources,” said Clive Nickolay, CEO of GE Gas Power’s Aeroderivative Business. “Our Center in Greenville has been a key industrial and talent hub for GE over the last five decades.

“The trust in our team combined with shop capabilities and prior experience with LMS100 Aero units are key reasons we chose Greenville for this expansion, as well as the desire to produce these units closer to increased customer demand for the technology across the Americas. This investment will help us better service power plant and industrial operators based in the Americas making an important contribution in reducing the carbon emissions of the power sector through the supply of flexible, dispatchable, and efficient power plants compared to earlier coal and gas power plants.”

The site, expected to add up to 25 skilled employees, will adopt lean methodologies to drive its transformation. Two new lean lines will be created to start manufacturing aeroderivative units from the fourth quarter of 2022.

New aeroderivative orders

Along with the investment in Greenville, GE also announced two orders for its aeroderivative technology.

This spring, West Texas Gas (WTG) ordered two GE LM2500Xpress turbines, delivering approximately 60 MW in total. WTG’s core businesses is natural gas distribution operations, natural gas transmission services, gas gathering/processing and natural gas liquids transmission services.

GE’s LM2500Xpress gas turbine package. (Photo: GE)

GE’s LM2500Xpress gas turbine package. (Photo: GE)

Each of the two LM2500Xpress power packages comprises of a GE LM2500 aeroderivative gas turbine modular package and emissions control system. With the capability to start in five minutes or even less from cold iron, these units derived from the aviation industry can perform daily starts and stops and will help WTG’s North Permian Midstream plant to process gas, GE said.

The first unit arrived at the site this summer and it is expected to start commercial operation in October, while the second unit is expected to be in commercial operation by year’s end.

GE also announced that it has secured a new order from the Greek construction company Terna SA for a GE TM2500 aeroderivative gas turbine to support the summer peak power needs and help the Greek Island of Kos avoid blackouts.

“PPC, the leading electricity producer and supplier in Greece, needed fast power to support the peak power demand during summer months in the power plant of Kos which supplies electricity to the island, as well as the surrounding islands of Kalymnos, Nisyros, Tilos, Leros, Pserimos, Telendos and Lipsi, with underwater cables” said Yannis Nousis, manager of Energy Projects at Terna SA. “GE had the ability to support the emergency situation in Kos through the immediate availability for shipment of their TM2500 aeroderivative mobile gas turbine technology and BOP equipment for fast power projects. GE’s power plant on wheels started to operate on July 18th, within 100 days from the date we signed the order with GE.”

The GE TM2500 can reach full power in less than 10 minutes with an efficiency of 37% at 60 Hz and 35% at 50 Hz, GE said, with the ability to operate on either natural gas or liquid distillate fuels. In Kos, due to the lack of natural gas, the 33.6 MW unit will be fueled by light distillate provided by a tanker every two to four weeks and stored in large tanks. It will be then purified by a GE supplied liquid fuel module and stored in smaller tanks for use in the TM2500 gas turbine generator.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM