Read this article in Français Deutsch Italiano Português Español

Jetstream of Houston adds hot water to waterblaster

02 October 2025

The 2000 Series is powered by Jetstream 2000 Series bareshaft pump, Rehlko or JDPS engine

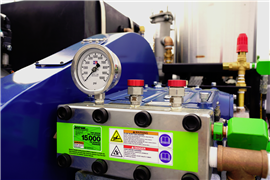

The 2000 Series hot water unit is powered by Jetstream’s 2000 Series UNx bareshaft pump, which the company said allows versatility by enabling a quick and easy three-step valve change process in the field to accommodate different pressure and flow requirements. (Photo: Jetstream of Houston)

The 2000 Series hot water unit is powered by Jetstream’s 2000 Series UNx bareshaft pump, which the company said allows versatility by enabling a quick and easy three-step valve change process in the field to accommodate different pressure and flow requirements. (Photo: Jetstream of Houston)

Waterblasting equipment specialist Jetstream of Houston LLP has introduced its first hot water pressure washer. Designed for difficult tasks such as graffiti removal, industrial concrete cleaning and removing grease from machinery, the new 2000 Series pairs the company’s UNx bareshaft pump with a diesel-fired 420,000-btu heater capable of up to 70° F temperature rise.

The new hot water unit has a 5,000-psi maximum operating pressure when using the burner and provides up to 19.8 gpm of heated water, which can be split between one and four guns. For standard waterblasting, the water pressure can be as high as 40,000 psi.

Bypass capability

The company said contractors can benefit from the new unit’s versatility since it can also be used as a standard waterblasting unit. When the heater is bypassed (the water heater has a 5,000-psi limit), the UNx pump can provide pressures ranging from 6,000 to 40,000 psi and flow from 19.8 to 2.9 gpm.

“The new hot water system operates at up to 5,000 psi, which is a lower pressure than our traditional waterblasting equipment but common for hot water applications,” said John Schaer, new products engineering manager for Jetstream in Houston, Texas. “The pressure can be higher if the heater on the unit is bypassed and a fluid end conversion installed, allowing contractors to use the same unit in a wider variety of applications, including those that require lower water pressure and hot water for commercial and industrial cleaning.”

High-reliability burner

Traditional burner heaters often wear out quickly and require frequent replacement, said the company. The 2000 Series hot water unit offers long service life and easy maintenance thanks to work the company’s engineering team did with advanced frequency analysis and vibration isolation as well as custom mounting.

“When we started the design process on this new unit, we tested a variety of different burners from different manufacturers and we saw the common failure points for this kind of system,” said Jonathan Isenhower, product manager, Jetstream of Houston. “If the burner is failing, it doesn’t matter how reliable your pump is. We did extensive testing on the burners and we developed some special vibration isolators that helps the burner last for a long time. We invested a lot of time and effort to make sure that the burner was highly reliable, in the same way the pump is reliable, so that the overall system would work well for our customers.”

The 2000 Series hot water unit from Jetstream of Houston is designed for applications where heat offers a more efficient cleaning option. (Photo: Jetstream of Houston)

The 2000 Series hot water unit from Jetstream of Houston is designed for applications where heat offers a more efficient cleaning option. (Photo: Jetstream of Houston)

User-friendly pump

Jetstream considers the UNx bareshaft pump part of its DNA. The pump’s fluid end design enables a quick and easy valve change process in the field, and the fluid end can be converted to different pressures and flows with a conversion kit to handle a wide range of applications.

The company said the pump is designed for easy maintenance and ease of repair with quick access to the packing, Uni-Valves and plungers. All of it can all be changed in the field with basic tools.

“The pump is extremely easy for anybody to work on,” said Isenhower. “You don’t need specialized training to repair the pump so it’s extremely user friendly. We think it’s the most user-friendly pump that exists for ultra high-pressure cleaning or industrial cleaning. We accomplish that through a cartridge-based design. The pumps are extremely durable, too. The whole pump is built to last.”

The 2000 Series hot water unit features a purpose-built control panel and pressure control devices, as well as an onboard 90-gal. water tank and charge pump that Jetstream said ensures a consistent water supply for uninterrupted blasting. The unit also includes a filtration system and hose rack.

Engine support

A diesel engine from Rehlko (formerly Kohler) or John Deere Power Systems rated 75 hp drives the pump and the water heater.

“We have a well-developed support team when it comes to picking and configuring the units,” said Isenhower. “Customers ask for different types of engine support depending on what’s already in their fleet. But when customers say, ‘Hey, I don’t know which one to get,’ I get them in touch with our support team, and we walk them through what the best system is for their application.

“They’re both really great engines that we have validated for this application, so we put a lot of work into making sure that the engines pair well with the pump so that everything lasts for a long time.”

Mobile or stationary options

Jetstream of Houston’s line of engine-powered waterblasters goes as high as 700 hp, and the 2000 Series is the company’s smallest to date.

“We wanted to do one with 75 horses because it gives you the ability to be mobile and have a very small footprint, while still offering very high performance,” said Isenhower.

The hot water system is mounted on a low-profile 5,000-lb. trailer in a configuration that is popular with rental customers. A galvanized steel frame prevents corrosion in even the harshest waterblasting conditions, said the company, while a properly rated torsion axle minimizes suspension wear.

The hot water model can also be ordered as a skid unit. “We see some potential here for an in-plant application – if they were going to be cleaning their own process equipment, or maybe doing surface prep or paint booth cleaning,” said Isenhower. “If you’ve got an automotive plant where you’re painting cars and you need to maintain those booths, that would be something that this system is suited for.

“Because we’ve got the burner on there, it’s a lot easier to remove greasy, sticky, certain kinds of gummy substances that can be a little bit trickier with cold water.”

Jetstream can also provide a package with an electrical motor for in-plant applications, and can offer support to companies that want to buy the pump and the burner and integrate them into a truck service body or an offshore rig, for example.

This article originally appeared in the September 2025 issue of Power Progress.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM