MAN Triton Platform Passes TAT In Japan

14 November 2019

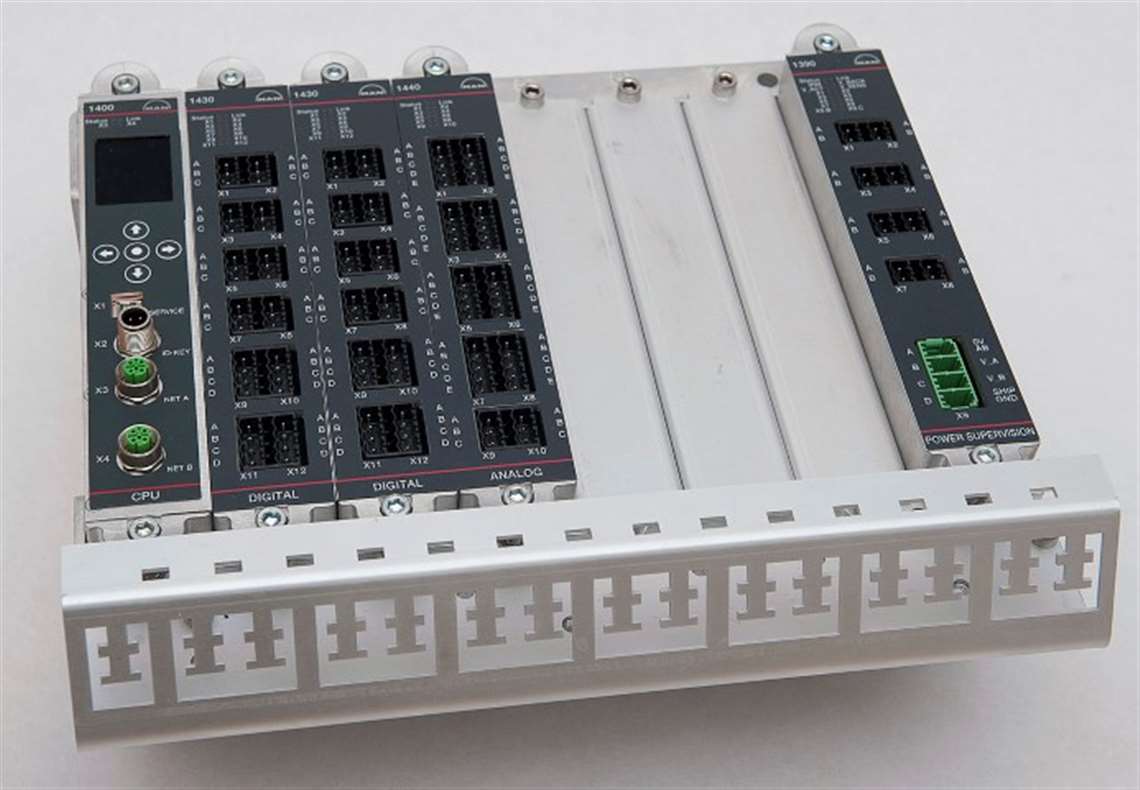

MAN Energy Solutions said its electronic ‘ME’ engine portfolio has reached another milestone with the announcement that its Triton platform recently passed its TAT (Type Approval Test) in Japan.

Developed at MAN Energy Solutions’ Two-Stroke Business Unit in Copenhagen, Triton is based on the experience accumulated over more than 20 years in the development and production of mission-critical electronics. The TAT was carried out in October on an engine provided by MAN Energy Solutions’ two-stroke licensee, Mitsui E&S Machinery, using the ME-engine’s latest engine control system, v.1903-2.

“This is a major milestone and sends a strong message to the market,” said Svend Krogsgaard, senior manager and head of Systems Automation Basic Platform at MAN Energy Solutions. “Triton is the new controller platform for our entire, two-stroke engine portfolio and is a future-proof solution characterized by its modularity, flexibility and scalability. Having such a stable, flexible foundation for our control software will benefit the future direction of our two-stroke technology immensely.”

Henrik R. Olesen, senior manager and head of Automation & Control Two-Stroke at MAN Energy Solutions, also praised the close cooperation between the classification societies, Mitsui E&S Machinery and MAN Energy Solutions that led to the successful TAT.

“This close collaboration with our industry partners is the backbone of our success,” Olesen said. “We have now shown that our engine control system runs just as well on the new Triton platform as it does on the existing Multi-Purpose Controller and have displayed the ease of switching from one system to the other. However, going forward, Triton delivers extra computing power and a faster network and I/O flexibility to face future demands; it also crucially encompasses cyber security by design.”

MAN Energy Solutions states that Triton will be introduced as a fully localized product, beginning in 2020. MAN said the new controller platform is characterized by its:

- increased engine flexibility for improved performance due to higher computational power and more advanced control functions

- advanced controls for increased fuel flexibility and emission reduction of the future

- modular architecture for future scalability

- preparation for simple interfaces towards other ship automation systems

- enhanced digital offerings

- ruggedness, high reliability and cost-effectiveness.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM