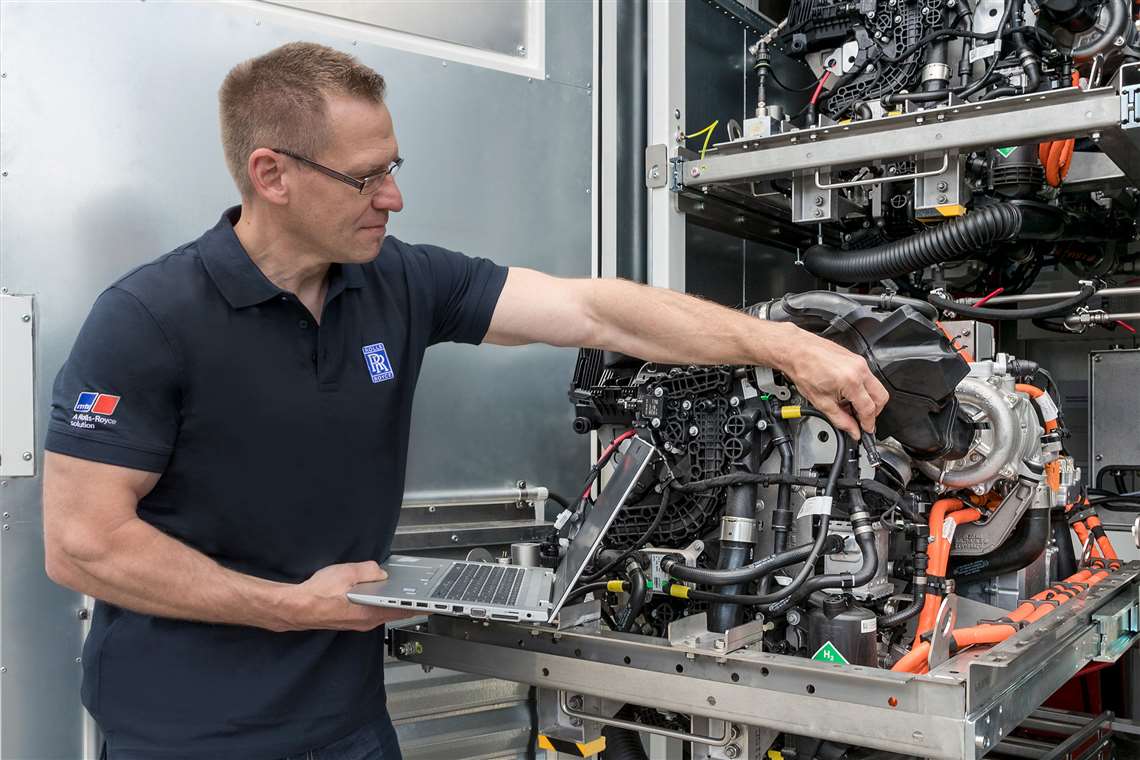

Rolls installing fuel cell demonstrator

10 June 2021

250 kW system located at company’s Friedrichshafen, Germany, plant

Rolls-Royce’s Power Systems is building a hydrogen fuel cell demonstrator to test future zero-carbon energy systems.

The 250 kW demonstrator at the company’s Friedrichshafen, Germany, plant, will be used for test purposes, and to show interested parties which applications the system is suitable for. These include standby power, prime power, uninterruptible power supplies (UPS) and black start capability. The system consists of fuel cell modules, batteries, fire protection, air conditioning and safety systems, cooling, gas supply and automation.

Rolls-Royce Power Systems is currently setting up a demonstrator in Friedrichshafen to test sustainable and climate-friendly power supply based on fuel cells in the future.

Rolls-Royce Power Systems is currently setting up a demonstrator in Friedrichshafen to test sustainable and climate-friendly power supply based on fuel cells in the future.

“We firmly believe that fuel cell technology is set to make a huge contribution to a successful energy turnaround. That’s why Rolls-Royce sees it as its mission to assume a pioneering role in fuel cell applications,” said Andreas Schell, CEO of Rolls-Royce Power Systems. “Fuel cells shall form an elementary part of our product portfolio for sustainable solutions.”

Fuel cells have very high efficiency levels when generating electricity from hydrogen and oxygen. When run on pure hydrogen, they give off zero emissions – only water vapor – as well as being low-noise, low-maintenance, and vibration-free.

“The greatest benefit is when they are run on regeneratively produced hydrogen because this enables polluting and climate-damaging gas emissions to be fully eliminated. This gives fuel cells a huge potential to become a major technology for decarbonizing propulsion and electrical power supply systems,” said Dr. Peter Riegger, Vice President Rolls-Royce PowerLab.

Over the past several months, the company has installed what it calls a complex hydrogen infrastructure at Friedrichshafen Plant 1.

Designed at the company’s plants in Ruhstorf (Bavaria) and Friedrichshafen, safety reasons dictate the container has two separate compartments for fuel cells and batteries, plus a host of power electronics. The control system has now been fully refined, cooling and air conditioning are on the roof, and a rack system enables simple maintenance, allowing individual system modules to be replaced as required.

The next step is to connect all four demo modules together in the container and hook up the batteries and power circuit. Commissioning is slated for the second half of 2021.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM