Read this article in Français Deutsch Italiano Português Español

MineSense, Komatsu partner on mining tech integration

26 September 2024

MineSense, a British Columbia-based provider of digital mining solutions, and Komatsu’s Modular Mining Systems, which supplies information management solutions for surface and underground mining operations, have executed a collaboration agreement to share data between MineSense’s ShovelSense technology and Komatsu’s Dispatch Fleet Management and ProVision Machine Guidance systems.

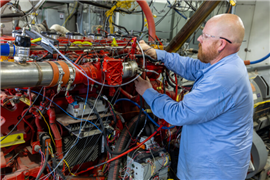

MineSense and Komatsu’s Modular Mining Systems have executed a collaboration agreement to share data between their mining technology solutions. (Photo: MineSense)

MineSense and Komatsu’s Modular Mining Systems have executed a collaboration agreement to share data between their mining technology solutions. (Photo: MineSense)

ShovelSense is designed to measure grade in each shovel scoop, enabling it to identify misclassified material at the mining face as trucks are being loaded. This means trucks can be re-routed to the correct dump location right away, without the need for additional handling costs.

The aim of the agreement is to provide customers with a pre-packaged, standardized, “plug and play” solution that exchanges loading cycle and material classification data in real time and provides automated notifications to re-route trucks when ShovelSense identifies a material mismatch. This will enable ShovelSense recommendations to be consistently actioned as truck diversions, without distracting equipment operators.

The standardized integrated solution can be purchased directly through MineSense as part of its ShovelSense solution, and can simply be switched on as part of its implementation. In addition to simplifying the procurement process through a single point of contact, the standardized solution will be regularly updated to ensure compatibility with future system upgrades and to protect against any new cybersecurity threats.

“Our goal is to make it as seamless as possible for customers to integrate ShovelSense into their mining operations,” said Frank Hoogendoorn, chief data officer at MineSense. “As anyone working on mining technology interoperability projects knows, data integration between third-party systems can be very challenging, especially when data sharing needs to be bi-directional, in real time and consistently reliable and secure. We’re pleased to be a Modular Ecosystem Partner and to offer a pre-built, “off the shelf” solution ready for immediate deployment.”

“We recognize we can create significant value for our customers by being an open data integration enabler,” Greg Lanz, general manager, Technology Interoperability at Komatsu, added. “The Modular Ecosystem is the future of digital mining collaboration, and we’re excited to see customers embracing integrations with our early adopter partners like MineSense.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM