A ‘radical’ retrofit product from Wärtsilä

30 March 2023

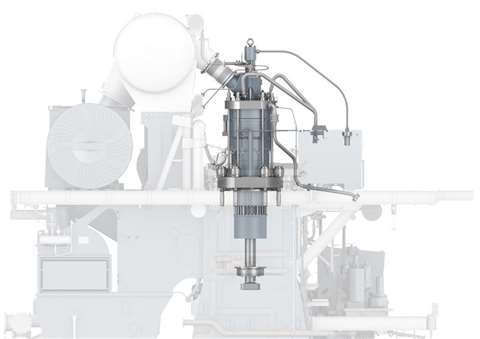

Fit4Power derating solution designed to reduce the bore size of two-stroke engines by 25%

Fit4Power solution reduces bore size of two-stroke engines while improving combustion efficiency for lower emissions. (Image; Wärtsilä)

Fit4Power solution reduces bore size of two-stroke engines while improving combustion efficiency for lower emissions. (Image; Wärtsilä)

Wärtsilä calls its new retrofit derating product a “radical” solution for two-stroke engines.

The Wärtsilä Fit4Power is designed to extend the emissions-compliant lifetime of merchant vessels by enabling ship owners to reduce the bore size of two-stroke engines by 25% while significantly improving combustion efficiency, which in turn reduces both fuel consumption and greenhouse gas emissions, the company said. This will improve the efficiency of existing fleets, ensuring compliance with Carbon Intensity Indicator (CII) regulations, and futureproofing assets against future environmental measures, the company said.

Wärtsilä 2-Stroke Services completed the pilot installation of Wärtsilä Fit4Power onboard a container ship with large-bore two-stroke main engine last year. The results showed that a vessel with this kind of main engine, which is now oversized for today’s operating patterns, can save 2000 tonnes of fuel and reduce at least 6000 tonnes of CO2 emissions annually thanks to this retrofit solution. Fit4Power received a certificate of product design assessment from the American Bureau of Shipping (ABS) in 2022.

“With the IMO’s CII now in force, operators of merchant vessels need cost-effective solutions that can assure the long-term fitness of their existing fleet,” said Ole Pyndt Hansen, managing director at Wärtsilä 2-Stroke Services. “Radical derating gives mid-life engines a new lease of life, with a power output and emissions profile that can take them through the early years of CII and prepare them for the most efficient use of new fuels needed to reach later emissions targets.”

While conventional derating merely tunes engines for operation at lower loads, Wärtsilä said the Fit4Power involves reducing the bore diameter of engine cylinders and introducing a new combustion chamber design, enabling the engine to run at optimal loads and with state-of-the-art fuel efficiency. The higher compression ratios and firing pressure achieved mean that the modified engine offers far greater efficiency than either conventionally derated engines or unmodified engines run at much lower loads.

Analysis from Wärtsilä shows that without modification, more than 80% of the global merchant fleet could fall into the lowest CII rating by 2030, requiring mandatory corrective action and risking losing business to more efficient vessels. Improving engine efficiency and optimization with solutions such as Fit4Power is one of the simplest and most cost-effective means of reducing emissions.

The solution is also a step towards the economical use of alternative fuels to meet future emissions reduction targets. It is designed to be compatible with Wärtsilä Fit4Fuels (Wärtsilä’s Two-Stroke Future Fuels Conversion Platform), a cost-effective retrofit solution enabling vessels to use LNG, methanol and ammonia fuels. By improving efficiency in line with CII requirements ahead of this next step, radical derating extends the CII compliant lifetime of the vessel by three to five years, giving shipowners valuable breathing space ahead of making a commitment to a future fuel – potentially more if owners opt for low or zero-carbon drop-in biofuels.

By substantially renovating mid-life engines, radical derating also benefits operators by both reducing ongoing maintenance costs, lubricating costs and extending the lifecycle of the main engine. Radical derating is currently available only for RT-flex96C engines.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM