Dana steers through changing landscape

10 May 2021

Electric motors roll off the line at Dana’s TM4 facility in Canada. Long a supplier of traditional powertrain products, Dana has more recently made significant investments to expand its electrification portfolio.

Electric motors roll off the line at Dana’s TM4 facility in Canada. Long a supplier of traditional powertrain products, Dana has more recently made significant investments to expand its electrification portfolio.

Electrification poses a significant emerging challenge for manufacturers of components and systems used in mobile off-highway powertrains. And that challenge has as much to do with the timing as the technology itself, as suppliers seek to balance investments and improvements in today’s conventional technologies with developing the e-mobility systems of tomorrow.

“It’s a changing landscape,” said Jeroen Decleer, general manager and vice president of mobile Europe for Dana Off-Highway Drive and Motion Systems. Dana has been among a handful of companies at the forefront of product development of both conventional and e-mobility technologies.

“Some of the key drivers include regulation, sustainability and social responsibility, and the total cost of ownership. These are happening across the world and at different speeds in every region,” added Decleer, who is also responsible for Dana’s global off-highway product management. “Internally, a key driver for us is reimagining product development to incorporate sustainability. You know, Dana has a unique role among mobility suppliers as our technology delivers power across the entire spectrum of vehicles, including the light, commercial, and off-highway markets.

“We have made some big commitments like support for the Paris Climate Agreement and reducing total annual greenhouse gas emissions – by at least 50% – before the end of 2035. It’s changing also on the electrification side. But we see innovation still on items which are not purely related to e-mobility.”

Traditional products

A good example of that is Dana’s recent introduction of a new drivetrain for rough-terrain cranes and terminal tractors (see details elsewhere in this issue), as well as the development of its Spicer TE50 powershift transmission, which was the Drivetrain Components of the Year at the 2020 Diesel Progress Summit.

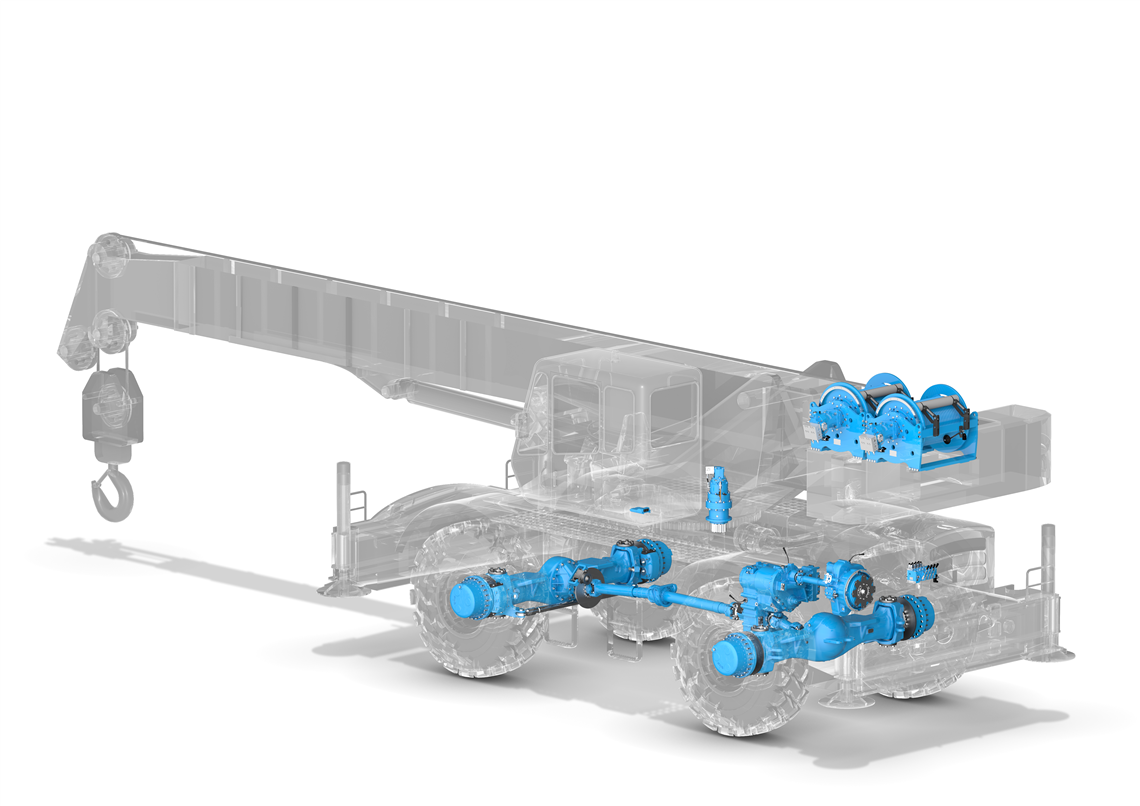

Dana’s new drivetrain for rough-terrain cranes shows how it continues to optimize conventional technologies.

Dana’s new drivetrain for rough-terrain cranes shows how it continues to optimize conventional technologies.

“Conventional powertrains are going to stay around for a while,” Decleer said. “The TE50 transmission is a very conventional powertrain and it’s taken off like a rocket for us in terms of success.

“With conventional powertrains, we’re still working on sustainability, still working on efficiency and performance and those remain good investments.”

Following its regional market approach, Dana also introduced both conventional and e-mobility products for China late last year. New track drives based on Spicer Torque-Hub planetary drives target both diesel powered and electric construction equipment.

Expanded presence

Dana also launched an integrated system for electric boom and scissor lifts with working heights above 6.0 m. The complete package incorporates Spicer Torque-Hub wheel drives, low-voltage internal permanent magnet motors, inverters, slew drives, pump-motor, system pumps, proportional valves, and electronic control units.

“We are expanding our presence with two major investments in India and China – but there is also a strong commitment to serve our North American customers using Dana’s expanded footprint and electrification know-how coming from Dana’s recent Brevini, Nordresa, Oerlikon Drive Systems, Pi Innovo, Rational Motion, and TM4 strategic acquisitions,” Decleer said.

“We are putting up a new plant in Chakan, Pune, (India), which is for our traditional drivetrains, but it is also a state-of-the-art facility in terms of electrification. There is a growing demand in Asian markets for traditional vehicles. For instance, MEWPs (mobile elevated work platforms) are taking off at a pace we haven’t seen in the U.S. or in Europe. It was below 100,000 a year before, and now we are seeing that doubling every couple of years.

An aerial view of Dana’s Off-Highway facility in Arco, Italy.

An aerial view of Dana’s Off-Highway facility in Arco, Italy.

“China’s changing. The number of vehicles they use per capita is still far below what we are used to in our more mature markets, so they are doing some catch-up. And they are catching up in the right way, investing also in the latest technology.

“In Europe, we see our investments pushing into certain areas where we have a leadership position – compact wheel loaders, telehandlers and of course ag equipment. For decades, those have been the signature applications we serve and will continue to lead the edge there in terms of breadth of portfolio, in terms of customers, and also in terms of technology, including electrification.

“Other sectors are also important. Port equipment which is rapidly changing, and also mining, where we predominantly are present in underground mining and you see electrification having different drivers. Our customers are asking us to invest into the revamp of those products.”

Dana has responding to those requests with both conventional products, such as an expanded hydrostatic and hydromechanical variable (HVT) transmission portfolio, and new e-mobility products such as new models of e-Torque-Hubs for scissor lift, turf equipment and mining and e-axle applications, as well as electric slew drives for mini-excavators.

Decleer also said Dana was in development of a new dual motor electric powershift transmission range for construction, mining and material handling machines that would debut in 2022.

“Dana is positioning itself to deliver more integrated and electrified solutions, but really to do that, your mechanical portion has to be state-of-the-art as well.” Jeroen Decleer, GM & VP, of mobile Europe for Dana Off-Highway

“Dana is positioning itself to deliver more integrated and electrified solutions, but really to do that, your mechanical portion has to be state-of-the-art as well.” Jeroen Decleer, GM & VP, of mobile Europe for Dana Off-Highway

“Electrification gives us the opportunity to rethink the way we look at applications,” Decleer said. “With typical applications, there are reasons why we have chosen conventional drivetrains over the years. Now, we have an opportunity to really look at that again. And with electrification, we’ve been forced to expand our capabilities and our expertise, not only to the drivetrain part of the duty cycle, but to the full vehicle duty cycle.”

Mixed approach

Overall, Decleer expects Dana to continue on the path of maximizing the performance and capabilities of its conventional technologies while pushing the envelope in e-mobility development.

“A mix is, I think, the right answer,” he said. “I think Dana overall is progressively shifting its resources into the electrified space. We are spending a lot more of our resources, percentage-wise, into the electrical components, through our acquisitions and our integration efforts.

“Dana is positioning itself to deliver more integrated and electrified solutions, but really to do that, your mechanical portion has to be state-of-the-art as well. So it’s not an ‘and’ story or an ‘or’ story - it’s the best of both worlds.”

www.dana.com/markets/off-highway

This story first appeared in the March issue of Diesel Progress. For a free print or digital subscription, click here.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM