Read this article in 中文 Français Deutsch Italiano Português Español

Digital camera interoperability in agriculture

10 September 2024

A new digital camera standard is underway in agriculture, and it will likely affect everyone.

Analog cameras of yesteryear are giving way to advanced digital camera systems. In agriculture, as farmers’ needs have evolved, higher quality cameras have become more commonplace.

“Somewhere along the line, the world went digital,” said David Smart, John Deere consultant, and a team lead in the Agricultural Industry Electronics Foundation (AEF). “So, the expectation for better cameras, higher quality and better image generation took hold.”

The boom in precision agriculture technology is allowing farmers to make data-determined decisions. Through the use of digital cameras and their systems, farmers have insights into things like soil conditions, irrigation needs and crop health. Prevalent applications now include such sophistication as agricultural robots, drones and large vehicles for auto farming.

Digital cameras have advanced to offer high resolution and can rotate their view, zoom into the region of interest, stream in different formats and change resolutions and frame rates. They can have LED lighting, or night vision; they have capability for configuration.

This precision ag trend is expected to continue as farmers look to increase productivity and profitability. According to Verified Market Reports, the Agricultural Camera and Monitoring Systems Market size was valued at USD $100 billion in 2023 and is projected to reach USD $194.87 billion by 2030, growing at a CAGR of 8.71% during the forecasted period 2024 to 2030.

“Digital cameras are playing a very important role in the agriculture industry, and yet they do not have the level of compatibility between brands that the industry needs,” said Smart.

Connection Complications

Plugging an off-the-shelf camera into a tractor, regardless of manufacturer, and plugging it in to work on the display in the tractor cab is currently a herculean effort. While farmers should be able to simply connect any camera into any tractor, it’s currently not possible.

“If you want to integrate the camera of another OEM, it will not work out of the box. You will have to modify your software application that you have on your display, and this usually takes minimally half a year to integrate a newcomer,” said Dennis Schäfer, Software Group leader, Motek GmBH, and deputy team lead of the AEF Digital Camera Systems (DCS) Project Team.

While there are multiple video standards that allow the transfer of video data, and there are standards that allow camera configuration, there is not a standard that allows for a zero-configuration, plug-and- play system.

“Digital cameras are playing a very important role in the agriculture industry, and yet they do not have the level of compatibility between brands that the industry needs.”

—David Smart, John Deere consultant and a team lead in the Agricultural Industry Electronics Foundation (AEF)

Most camera systems that are for use through a terminal inside a tractor are based on analog cameras, where each camera is typically wired with a separate cable to deliver the camera image into the operator cabin for display. Many times, operators want to view several cameras simultaneously, which may increase the complexity of that system.

“Currently, even if a farmer has an analog or digital camera system in his tractor, he may need to buy an extra terminal for a new implement camera system because it has a different connector type, or the camera is using a different protocol,” said Smart. “There is an existing camera standard, but it is completely inadequate for the plug-and-play expectation that every camera will work equally well with the terminal.”

HSI Backbone

Originally unveiled 23 years ago, ISOBUS refers to the ISO 11783 standard “nervous system” of ag equipment that seamlessly connects tractors to implements and aftermarket options such as displays and joysticks, etc. With ISOBUS, machines work together as a system better than each component can work on its own.

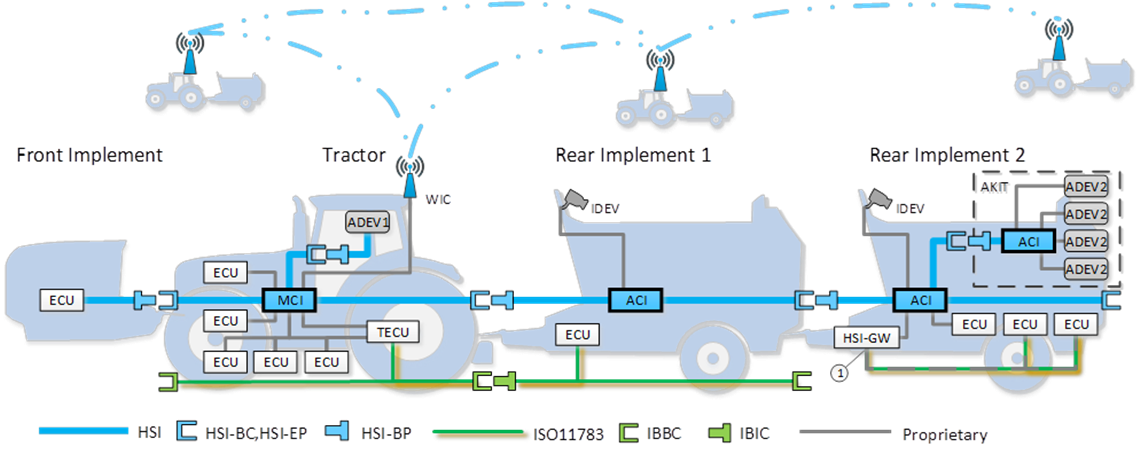

This diagram shows a “reference architecture” for imagined HSI systems and the connectivity. Today’s ISOBUS (ISO11783) does not go away, even as the diagram focuses primarily on HSI. The connectivity to front and rear implements, cameras, aftermarket devices (ADEV1), aftermarket kits (AKIT) and even to other nearby machines using Wireless Infield Communications (WIC) is represented. (Illustration: Agricultural Industry Electronics Foundation)

This diagram shows a “reference architecture” for imagined HSI systems and the connectivity. Today’s ISOBUS (ISO11783) does not go away, even as the diagram focuses primarily on HSI. The connectivity to front and rear implements, cameras, aftermarket devices (ADEV1), aftermarket kits (AKIT) and even to other nearby machines using Wireless Infield Communications (WIC) is represented. (Illustration: Agricultural Industry Electronics Foundation)

The AEF, a global non-profit organization founded to improve cross-manufacturer compatibility in agricultural equipment, demonstrated the next generation of ISOBUS, known as High Speed ISOBUS (HSI), for the first time at its North American Plugfest in 2022. With greater bandwidth and faster connection speed – roughly 4,000 times faster than the original technology – HSI will open new opportunities for innovation now and into the future as even more performance and automation are demanded.

AEF, in close collaboration with ISO Technical Committee 127, Sub Committee 3, and Joint Working Group 16 – responsible for both next-generation HSI and the existing camera standard – are working to update the existing camera standard with new requirements that will focus on making cameras and monitors fully plug-and-play capable.

“Beyond the original mission of the HSI team to create the technology for much higher performance command and control of implements, digital cameras were the very first [new] use case based on HSI on the HSI infrastructure, and then wireless infield communication to use those cameras was the second. So, these are all interlocked because of the advantages these cameras bring to the industry,” said Ryan Milligan, deputy communications and marketing, AEF.

“The main backbone aspects of HSI need to be there for the cameras to have a place to plug in. Otherwise, you’re back to creating a whole other private network,” said Smart.

Digital Camera Team

The AEF created a Digital Camera Systems (DCS) Project Team, uniting over 20 digital camera experts from AEF member companies spanning the United States, South America, Europe and Asia, to improve cross-brand interoperability and integration of digital cameras.

The new standard will allow farmers to be able to choose an HSI-compliant camera and an HSI-compliant monitor that best meet their needs. For example, they may want a smaller (or larger) monitor than the stock offering, and similarly they can choose a camera based on its capabilities (e.g., resolution, day/twilight/night capability, etc.). The integration of cameras and monitors into an HSI system, in a standardized manner, will allow the use of any HSI conforming or compliant camera that meets a minimum set of expectations; you can just plug it in and it works.

“In the analog world, if you have 15 cameras on your implement and you wanted to show all these 15 cameras on your machine, you either have to add some specialized and expensive hardware that mixed the video into a single stream for one cable or you have to run 15 cables from your implement to your machine because the existing ISOBUS data line is just not compatible with analog video communication and not capable of the high data rate that would be required to transmit digital video streams,” said Niklas Niebrügge, ANEDO GmbH, a software developer with expertise in digital video system solutions and leader of the AEF DCS Project Team.

“Our mission is to provide a new AEF functionality to enable plug-and-play, off-the-shelf video solutions that offer vision system component interoperability and easy integration for manufacturers and aftermarket sales in the context of HSI infrastructure,” he said.

“Due to digitalization by HSI infrastructure and the standardization of the camera interfaces, you can run multiple video streams through just a single cable and reduce complexity and costs of the wiring harness,” Niebrügge explained. “That, in combination with the plug-and-play system, will be an incredible tool and a big leap forward for the entire industry.”

Once the basic work is completed for simple process monitoring and plug-and-play component interoperability, the door is open for other use cases and also for collaboration with different AEF functionalities for precision farming. This factors into, for example, wireless infield communication and the ability to detect different objects and distribute this information on the machine, ultimately allowing for an entirely interoperable future.

Looking Down the Road

While some use cases have not yet been imagined, a prime goal of the HSI team is to develop the foundation for a new industry communication standard that can scale for many years to come.

To ensure that scalability, each use case and derived requirements are explored individually for how those requirements may change in even more futuristic systems. The HSI team then translates that composite work into an architecture that supports major advancements beyond what we know about today.

The new standard will allow farmers to be able to choose an HSI-compliant camera and an HSI-compliant monitor that will best meet their needs. (Photo: KHL Staff)

The new standard will allow farmers to be able to choose an HSI-compliant camera and an HSI-compliant monitor that will best meet their needs. (Photo: KHL Staff)

“This is, of course, no small challenge – to know what we don’t yet know,” said Smart.

“One of the main tasks for us is to extend and improve the ISO 17215 standard (Road vehicles — Video communication interface for cameras) to make it usable for the complex mixed fleet tractor-implement combinations we have in ag,” said Niebrügge.

According to Niebrügge, this makes it suitable for the truck and trailer, construction and earthmoving machinery and mining industries, as well.

“I think it will spread over other industries… down the road because this is not a new problem. The entire non-moving, stationary application fields will probably use this standard, as well,” said Schaefer.

“Digital ethernet cameras are kind of new on vehicles, but we’ve been using them for local and house security surveillance for years. However, there is no standard that just allows you to plug a camera into a network,” he continued. “It will show up on your computer terminal at the end of the day unless you have the software from the manufacturer and the camera from the same manufacturer.

“So, the stationary application fields will probably use this standard, as well. The need for a plug-and-play camera system can spread significantly wider than just these industries that we’re currently talking about.”

Simply Genius

Albert Einstein reportedly said: “Any intelligent fool can make things bigger and more complex... It takes a touch of genius and a lot of courage to move in the opposite direction.”

The AEF HSI and DCS Project Teams are developing a complex technology with the goal to make it simpler, both for the customer and the end user.

“When the DCS team has completed their work, any HSI conforming camera will be compatible with every HSI conforming monitor/display,” said Smart.

The team estimates the new ISO standard to be available globally by 2027.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM