Infinitum introduces electric traction motor

10 January 2023

Liquid-cooled motor designed for applicaitons that drive, fly or sail

The Aircore Mobility motor replaces the copper wound iron stator found in traditional motors with a lightweight, printed circuit board (PCB) stator. (Photo: Infinitum)

The Aircore Mobility motor replaces the copper wound iron stator found in traditional motors with a lightweight, printed circuit board (PCB) stator. (Photo: Infinitum)

Round Rock, Texas-based Infinitum has introduced Aircore Mobility, an axial flux propulsion and traction motor designed for passenger vehicles as well as aviation, marine, construction, agricultural machines and auxiliary equipment. The company said the motor delivers high power and torque density and operates with efficiency over a wide range of speeds and load conditions to maximize vehicle range.

The new motor was designed to replace the copper wound iron stator found in traditional motors with a lightweight, printed circuit board (PCB) stator that the company said is 10 times more reliable. When compared to conventional motors, Infinitum said it is 10% more efficient, 50% smaller and lighter, and uses 66% less copper.

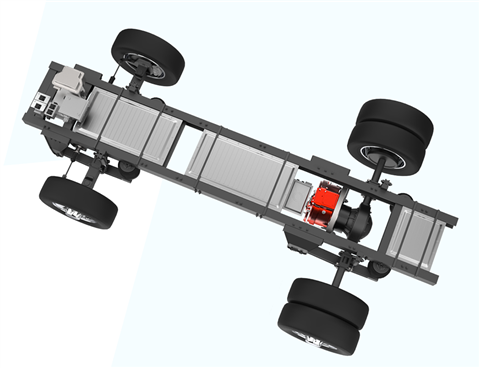

Ben Schuler, Infinitum’s CEO and founder, invented the PCB stator technology at the heart of the company’s motor innovation. (Illustration: Infinitum)

Ben Schuler, Infinitum’s CEO and founder, invented the PCB stator technology at the heart of the company’s motor innovation. (Illustration: Infinitum)

“Our Aircore motor topology eliminates core losses and delivers a broader range of speeds and load conditions where the motor can operate at high efficiency levels,” said Paulo Guedes-Pinto, vice president of technology for Infinitum. “The Aircore Mobility motor offers a new avenue in extending range for Class 1-8 vehicles, aerospace, marine, construction and agricultural machines.”

Infinitum said the motor is designed and manufactured with a sustainable, circular lifecycle. The motor can be produced using fewer raw materials and its modular design allows the housing, rotors, and stators to be reused multiple times, giving parts a second and third life to serve future generations. The motor can also be manufactured almost anywhere locally without complex assembly equipment.

The company also said that its smaller size means more product is shipped in equal space, which drastically reduces transportation related emissions.

The motor is covered by 32 issued patents and 44 pending patents and is expected to be available in Q2 2023.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM