More details on Kohler’s KSD

03 February 2022

Why Kohler is making a big move with smaller engines.

Aiming to provide flexibility for both mobile and stationary applications, the company has unveiled a new range of compact diesels that will be offered in naturally aspirated, turbocharged and turbocharged charge-air cooled versions to meet exhaust emissions regulations in the U.S. and EU, as well as new emissions standards in India (Bharat Stage 5 in 2024), China (Stage 4/Stage 5), Japan and Korea.

Kohler has unveiled a new range of small diesel engines for mobile and stationary applications. The Kohler Small Displacement (KSD) engines will be available globally in naturally aspirated, turbocharged and turbocharged charge-air cooled versions.

Kohler has unveiled a new range of small diesel engines for mobile and stationary applications. The Kohler Small Displacement (KSD) engines will be available globally in naturally aspirated, turbocharged and turbocharged charge-air cooled versions.

The new Kohler Small Displacement (KSD) are the company’s most significant engine development since the launch of the Kohler Direct Injection Diesels in 2017 and comes in one of the most competitive segments of the global engine market.

“Choosing the right engine for any equipment, from gen-sets to specialty machines, requires time and significant investment,” said Vincenzo Perrone, president of Kohler Engines. “We at Kohler are convinced that a global product must be conceived and designed with a global approach suitable for all regions compliant with all norms worldwide, compatible with all kinds of machines.

“With the KSD we are bringing the level of technology available on larger platforms to compact engines. We are offering the latest technology to deliver the best performance for every new or existing machine worldwide.”

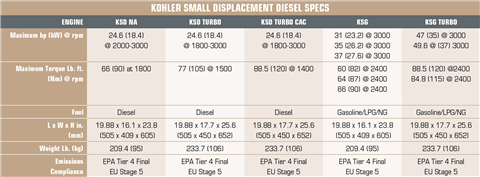

The KSD engines are three-cylinder engines with bore and stroke dimensions of 81 x 90 mm and an overall displacement of 1.391 L. The naturally aspirated models will offer ratings of 24.6 hp (18.4 kW) at 2200 rpm, with maximum torque of 66 lb. ft. (90 Nm) at 1800 rpm.

The turbocharged engines will have the same maximum horsepower, with torque rising to 77 lb. ft. (105 Nm) at 1500 rpm while the turbocharged and charge-air cooled engines will see torque top out at 88.5 lb. ft. (120 Nm) at 1400 rpm.

The KSD will also be available at launch with EU Stage 5 and EPA Tier 4 final generator set ratings. For the 50 Hz markets, standby power ratings will be 17.4 hp (13 kW), 22.1 hp (16.5 kW) and 25.2 hp (18.8 kW), while prime power ratings are 15.6 hp (11.7 kW), 19.9 hp (14.9 kW) and 22.9 hp (17.1 kW). All 50 Hz ratings are at 1500 rpm.

For the 60 Hz markets, standby ratings are 22.7 and 24.6 hp (17 and 18.4 kW), while prime ratings are 21.8, 22.7 and 24.6 hp (16.3, 16.7 and 18.4 kW), all at 1800 rpm.

The new KSD engines are intended to eventually succeed the existing Kohler KDW series engines. The engines are a completely new design that was heavily influenced by Kohler’s OEM customers. “With this engine, we had a lot of early conversations and we partnered with some of our OEMs and got input from them even before the design,” said Jeff Wilke, Industry Channel Manager – Engines at Kohler. “It’s a clean sheet design like the KDI engines and our targets were best-in-class performance, total cost of ownership – we know that’s a focus for our customers these days – heavy-duty design and unique technical solutions.

“The people who have given us input have seen the result of that input in this engine.”

The KSD engines incorporate an electronically controlled indirect injection (IDI) system in which fuel is delivered into a pre-chamber where it is mixed with air and ignited before passing into the combustion chamber where the combustion cycle is completed. The system uses low pressure (250 bar/3600 psi) fuel injectors based on gasoline direct injection (GDI) technology.

The naturally aspirated KSD engines will offer ratings of 18.4 kW (24.6 hp) at 2200 rpm, with maximum torque of 90 Nm (66 lb. ft.) at 1800 rpm.

The naturally aspirated KSD engines will offer ratings of 18.4 kW (24.6 hp) at 2200 rpm, with maximum torque of 90 Nm (66 lb. ft.) at 1800 rpm.

The fuel system is designed to provide precise fuel metering and strong load response, along with good performance at altitude. The control electronics also allow for prognostics, diagnostics, and remote monitoring, as well as integration with other machine systems through CAN J1939 communications networks.

“It is a state-of-the-art indirect injection system but has the specific electronic management typical of direct injection engines,” said Massimiliano Bonanni, general manager, Product Strategy for Kohler Engines. “Major benefits are the engine performance is maximized in any operating conditions and environments, at sea level as well as in high altitude. And responsiveness is outstanding, as the system offers a very limited speed droop, as well as isochronous control if required, like in bigger displacement common rail engines.

“These translate into machine productivity and comfort. This amazing low-end torque lets the operator run his piece of equipment at lower rpm and save fuel. Moreover, the electronic injection system allows for no visible black smoke.”

Kohler said the KSD engine is designed to fit in the same application envelope where 1.1 L engines are currently used - thus providing a drop-in replacement to competitive engines - while still delivering the horsepower and torque performance of a 1.7 L engine.

“It’s almost 1.4 L, however, it’s in the package size of a 1.1 L engine,” said Wilke. “It’s very compact,” with length, width and height dimensions of 19.88 x 16.1 x 23.8 in. (505 x 409 x 605 mm) for the naturally aspirated engines and 19.88 x 17.7 x 25.6 in. (505 x 450 x 652 mm) for the turbocharged engines. The weight ranges from 209.4 lb. (95 kg) for the naturally aspirated engines to 233.7 lb. (106 kg) for the turbocharged models.

“When you look at this market now at 19 kW and you look at the engine displacements, they range from 900 cc to 1.7 L that have all been pushed all into this same area,” Wilke said. “So our idea is we went more in the middle with 1.4 L, while providing all kinds of torque and performance.

“We at Kohler are convinced that a global product must be conceived and designed with a global approach suitable for all regions compliant with all norms worldwide, compatible with all kinds of machines.” - Vincenzo Perrone

“We at Kohler are convinced that a global product must be conceived and designed with a global approach suitable for all regions compliant with all norms worldwide, compatible with all kinds of machines.” - Vincenzo Perrone

“When you look at most engines in this range, they’ve got to be pretty large displacement before they can even get close to 120 Nm torque. In most cases, you’re looking at close to a 1.7 L engine to be able to do that.”

Even with its compact dimensions, Wilke said the KSD “is a heavy-duty design.”

“Our KDW engine wasn’t perceived as a heavy-duty engine because it has an overhead cam that was belt-driven,” Wilke said. “People just saw that it had a belt and that’s just not seen as heavy-duty.

“This engine goes back to the in-block cam design that is very robust. It also has large bearings to handle the higher loads of applications where larger displacement engine were used and now can be replaced with the KSD due to the robust design.”

Kohler said the drop-in capability of the KSD engines is enabled by a range of features that includes:

- A fully adjustable cooling fan mount, allowing three different fan positions and eliminating any radiator repositioning in the application. “You don’t need to reposition the radiator because the cooling fan is fully adjustable,” said Bonanni. “We put it where you need it.”

- A dual side service capability. “The oil filter, oiI dipstick and fuel filter can be located on the preferred service side,” Bonanni said.

A third power-takeoff (PTO), available, as well as a non-PTO option.

- Standard 500-hour oil change interval with 1000-hour intervals available for select applications. “The KSD provides extended oil service intervals, Bonanni said. “In fact, the focus on clean combustion drives low oil consumption and avoids oil dilution as well as heavy sooty oil contamination. This is thanks to its unique piston design, a dedicated in-house honing machining process and a specific crankcase ventilation system with a cutting-edge design.

“In addition to that, the KSD offers a 2000-hour heavy-duty poly-V belt solution. Service intervals have been extended more than ever. We offer outstanding performance along with electronics and do not require any kind of machinery redesigning from OEMs.

“As a result, the KSD offers a drop-in solution for existing applications, making no further investment needed.

Kohler plans to begin production of the KSD engines at its Aurangabad, India, facility at the end of 2022. “We are building a new portion of our Aurangabad plant,” said Nino De Giglio, director, Marketing Communication and Channel Management for Kohler in Italy. “And it’s not just building a new building, the processes of the assembly line will be very innovative.”

The company also has plans to develop spark-ignited versions of the KSD engine that will be capable of operating on gasoline, natural gas and LPG. Those engines, currently expected to launch in the 2025 timeframe, will also be available in naturally aspirated (23.2 to 27.6 kW/31 to 37 hp) and turbocharged (35 to 37 kW/47 to 49.6 hp) models.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM