Read this article in French German Italian Portuguese Spanish

Hatz Components provides precision machining

01 May 2025

When Power Progress spoke with Dr. Sebastian Wohlgemuth at Bauma 2025, the newly appointed CEO of Hatz Components GmbH (Hatz Components) was only nine days into the role. Yet, he is no stranger to the company or its innovations, having joined Motorenfabrik Hatz GmbH (Hatz) in December 2020, where he served as director of Research & Development.

Hatz Components has been in existence since the 1980s. It was split off as an independent company in late 2021. (Photo: Hatz Components)

Hatz Components has been in existence since the 1980s. It was split off as an independent company in late 2021. (Photo: Hatz Components)

“In this position, I was responsible for product development in general and also for concepts,” he said. That included the Concept Cube project, a unique modular eDrive system first shown in model form at Bauma 2022. “With the Concept Cube 2.0 at Bauma 2025, Motorenfabrik Hatz and Hatz Components were meeting because Hatz Components machined some parts for the Cube.”

The business Wohlgemuth now leads has been in existence since the 1980s. It operated as part of Motorenfabrik Hatz until December 2021, when it was split off into a separate independent company.

“The company seems to be new because it’s just three years old, but Hatz itself is 145 years old and the components business is more than 40 years old,” said Wohlgemuth. “Hatz Components has long partnerships. It also has a long history within Hatz.”

Dr. Sebastian Wohlgemuth, Hatz Components CEO (Photo: Becky Schultz)

Dr. Sebastian Wohlgemuth, Hatz Components CEO (Photo: Becky Schultz)

Focus on expansion

Based in Ruhstorf an der Rott, Germany, Hatz Components manufactures high-precision metal components for various industries, such as the global automotive and commercial vehicle industry and manufacturers of agricultural vehicles. Over its history, the company has become a renowned supplier of connecting rods (conrods) and crankshafts, which make up its main business.

Now, the company is looking to expand into other products and services, including custom machining and prototyping.

“We have highly flexible machining centers for small and big volumes, which gives us possibilities to make other parts besides connecting rods,” said Gordon Sauer, director Sales at Hatz Components. “Prototyping is also really important. That’s often the entry into serial production.”

As a supplier to Motorenfabrik Hatz, Hatz Components has the capability to machine a wide range of engine parts. “We also do our own machining tools – clamps and fixtures – to grant short delivery times and high flexibility for our customers,” Sauer stated. “We produce four of the five Cs* at Hatz Components.”

Currently, external business makes up roughly 70% of the total business for Hatz Components. Wohlgemuth plans to grow that to an even larger percentage of the whole.

“One of the focus points is to extend the external business,” he said. “Be a strong supplier and partner to all of our customers – that’s one of our key values.”

Prototyping capabilities displayed

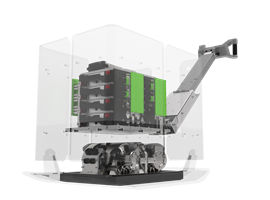

The company’s prototyping competence was on display at Bauma 2025 within the Concept Cube 2.0. Whereas the model shown three years ago represented Hatz’s vision for the future of soil compaction, the latest iteration brings that vision to life, with a working model demoed in an outdoor exhibit area at the 2025 event.

The four motors of the Concept Cube 2.0 are mounted on a prototype base specifically machined by Hatz Components for the application. (Photo: Hatz Components)

The four motors of the Concept Cube 2.0 are mounted on a prototype base specifically machined by Hatz Components for the application. (Photo: Hatz Components)

Concept Cube 2.0 is a prototype demonstrator unit designed to show Hatz’s technology competence in the field of electric drives and to present the planned scope of delivery, Its eDrive system is designed as a very compact drivetrain with an innovative imbalance system.

“For this system, very complex machined parts are used to carry the electric motor imbalance units,” Sauer pointed out. “These parts have been machined by Hatz Components and show its competence besides the connecting rods business.”

“What is special about the system is that the imbalances are directly mounted to the motors. Normally, you have something in between there to drive the imbalances – a belt or hydraulics,” Wohlgemuth commented. “In our system, there is nothing in between, which means there are no losses. So, we have designed a highly efficient drive system.”

The motors are mounted on a base that was machined from a solid block by Hatz Components specifically for the application. “It’s a prototype part that’s critical because of the high mechanical stress on it,” Wohlgemuth explained. “It’s hard to machine due to the complex structured design with tight tolerances in the finished machined areas.

“In the prototype business, you have to be able to react fast. So, there we also show the competence of Hatz Components,” he continued. “Hatz Components is famous for conrods, and probably people don’t know that we’re also capable of machining parts from solid/billet. That’s a business we want to expand in the future.”

Its custom machine and prototyping capabilities represent an opportunity to not only add to its customer base but grow its longstanding partnerships beyond their current form.

“I want to build on those partnerships and expand our portfolio beyond conrods to have a better common portfolio of parts,” Wohlgemuth said. “My vision is to become known for parts other than conrods.”

*Crankshafts, connecting rods, crankcase, cylinder heads and camshafts

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM