WinGD touts fuel savings of dual-fuel engine

05 April 2022

8% savings in gas mode achieved in testing; first engine to go into operation in 2023

WinGD said its X-DF2.0 engine technology has surpassed initial expectations in terms of fuel savings.

According to the company, optimized engine settings on WinGD’s X-DF2.0 second-generation dual-fuel engine platform have achieved fuel savings of up to 8% in gas mode and up to 6% in diesel mode during recent tests at CMD (CSSC-MES Diesel Co) in Shanghai, China.

Since its launch in 2013, WinGD’s X-DF engine series has become the world’s best-selling low-pressure two-stroke dual-fuel engine with over one and a half million running hours to-date. Building on the original X-DF engine series, the second-generation X-DF2.0 platform was launched in 2020, with ambitious greenhouse gas (GHG) reduction targets in mind. Since that time, more than 60 engines have already been ordered, signaling the industry’s strong commitment to the energy transition, WinGD said.

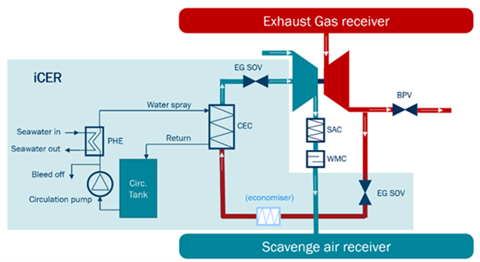

WinGD’s Intelligent Control by Exhaust Recycling (iCER) became the first technology to be introduced to the X-DF2.0 series to reduce fuel consumption and cut methane emissions. iCER further reduces methane slip by 50% compared to the first generation X-DF and lowers fuel consumption in both diesel and gas mode. The technology also enables Tier III NOX compliance in liquid fuel mode without the need of additional Selective Catalytic Reduction (SCR) NOx reduction technology.

Volkmar Galke

Volkmar Galke

Retrofittable for future fuels, the dual-fuel platform offers flexibility for the future.

The first delivery of the X-DF2.0 is due to be in operation in 2023 onboard two newbuild pure car and truck carriers (PCTC) running on LNG as fuel. The project will not only showcase WinGD’s core engine development expertise but also their extensive knowledge in the optimization potential of integrated hybrid systems, a solution also developed and being delivered to WinGD customers.

“We always knew that our X-DF technology offers the greatest optimization potential for operators looking to reduce emissions,” said Volkmar Galke, director, Sales for WinGD. “However, ongoing test results are proof of engine concept beyond expectations which we believe puts our X-DF2.0 portfolio and holistic energy management solutions at the forefront of shipping’s energy transition.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM