Read this article in Français Deutsch Italiano Português Español

CIMAC 2025: Decarbonising maritime transport

14 August 2025

Reducing GHGs in maritime shipping was a primary topic of this year’s CIMAC conference. Here, we take a look at some related presentations from the event

Conference attendees at the CIMAC gala dinner (Photo: CIMAC)

Conference attendees at the CIMAC gala dinner (Photo: CIMAC)

Taking place every three years, the CIMAC Congress brings together delegates involved in development, production, deployment and testing of internal combustion engines used across a series of applications, including marine/ship propulsion, rail traction and power generation.

The congress moves its location between member nations for each triennial event; the last edition was held in Busan, South Korea in May 2023 after being postponed due to the COVID pandemic. For 2025, the conference was held in Zurich, Switzerland. While speakers presented papers on a series of topics, including digital connectivity and system integration, the predominant emphasis was on technologies intended to help decarbonise engines used in maritime transport.

IMO emissions targets

Introduced on January 1, 2020, the IMO 2020 (International Maritime Organization) stipulated that the maximum permitted sulphur content in fuel oil used in shipping be reduced from 3.5 to 0.5% to reduce sulphur oxide (SOx) emissions. This is mandatory for all ships, except for those operating in Emission Control Areas, where sulphur content is already limited to 0.1%.

Part of the International Convention for the Prevention of Pollution from ships (MARPOL), the new limit was anticipated to deliver a 77% cut in overall SOx emissions, equivalent to an annual reduction of approximately 8.5 million metric tonnes of SOx.

In addition to this, the IMO introduced its Revised Greenhouse Gas (GHG) Strategy in 2023. This has a series of targets to be reached over the coming decades, including a 20 to 30% reduction in GHG emissions by 2030, a 70 to 80% reduction by 2040 and achieving net-zero GHG emissions by 2050 (GHG emissions do not have to be zero at point of emission if they are off-set in some way).

Decarbonising fuel

Fuels other than diesel oil in combination with new engine tech will need to be adopted to achieve this ambitious net-zero target. Hydrogen and ammonia are fuel types which can support improved efficiency of diesel fuel when used in a dual-fuel engine. In his paper, ‘Decarbonising maritime power systems with hydrogen and ammonia integration’, Sadi Tavakoli from SINTEF Ocean examined the potential for emission reductions when using a dual-fuel system.

Based on 280 days of real-world fuel usage data collected from a Norwegian freighter, analysis using the FEEMS (Fuel Emissions Energy Calculation for Machinery System) modelling framework showed that it would be possible to cut emissions by introducing hydrogen- or ammonia-powered engines. It was noted, though, that sourcing green variants of either fuel was fundamental to achieving the greatest GHG emissions reductions.

Methanol benefits

Another alternative fuel that offers the potential to reduce GHG emissions is methanol. ‘Methanol Dual Fuel Engine Development Status’, presented by Yoshinori Kaji of Daihatsu Diesel MFG, covered how the company is advancing its investigations with the goal of delivering efficient use of methanol fuel in an internal combustion engine.

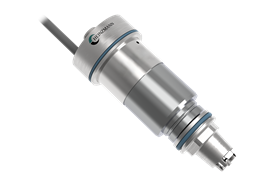

Methanol port Injector from Heinzmann (Photo: Heinzmann)

Methanol port Injector from Heinzmann (Photo: Heinzmann)

At this year’s CIMAC conference, Heinzmann presented a production-ready port injector for use in medium-speed engines using methanol fuel.

The new injector supports dual-fuel operation in low-pressure applications, for both new models and engine retrofit projects. The injector can deliver an atomised fuel mist at pressures of between five and 20 bar.

Features of the new injector include a CFD-derived cone angle that creates a uniform spray for stable ignition, while a double-wall option supports related safety standards.

There are two methods for introducing methanol to an internal combustion engine, port or direct injection. While port injection has the advantage of a lower injection pressure (about 60 bar), this method can sometimes result in ‘abnormal’ combustion. Because of this, the decision was made to use direct injection. As the fuel is introduced at about 600 bar it will quickly vaporise, but this method also requires a higher engine compression and injectors which can deliver both methanol and diesel fuel.

Daihatsu is continuing to work on development of its dual-fuel direct-injection engine for marine applications.

Engine oil impact

As mentioned earlier, ammonia is a fuel being investigated for its potential to cut marine emissions. But unlike heavy fuel oil, ammonia has little lubricative properties, meaning that engine oil has to work harder to reduce friction and maintain an acceptable engine temperature.

Welcome reception at the CIMAC conference (Photo: CIMAC)

Welcome reception at the CIMAC conference (Photo: CIMAC)

‘Lubricants enabling alternative fuels for maritime decarbonisation’ was put forward by Edward Ng from Gulf Marine, a company which has carried out studies to determine whether alternative fuels such as ammonia can have a detrimental effect on the engine oil.

According to the conclusions put forward in the report, while not all bench tests indicated a performance detriment, some did show performance degradation in final-aged oils. It was noted that tests of oils when using ammonia as fuel did not reveal any ‘severe impairment’ in oil performance.

A list of available papers presented at the CIMAC Congress 25 is available by clicking here.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM