How Poclain ‘renewed and evolved’ its electrohydraulic braking valve solutions

08 February 2022

Company updates electrohydraulic braking valve solutions for mobile equipment

With an eye toward current regulations as well as future electrohydraulic, intelligent and autonomous machines, Poclain Hydraulics said it has “renewed and evolved” its electrohydraulic braking valve solutions for mobile equipment.

Along with the renewal of the products, the company is aiming to expand the application of its technologies. According to Primož Pangeršič, Poclain’s product portfolio manager responsible for brake valves and product development globally, the company’s traditional markets have included tractors and other agricultural equipment. “But we are targeting other markets as well with those products, as they were designed for multiuse purposes,” he said.

The company’s updated offering includes:

Steering assist braking valves: The valves are a compact, all-in-one design with integrated electronic control making it optimal for current equipment, as well as future intelligent, semi-autonomous or autonomous machine. The valves are available for machines that operate at speeds under 25 mph (40kph) and allow for automatic disengagement at higher speeds, with the electronic control enabling automatic cut-off at high vehicle speed.

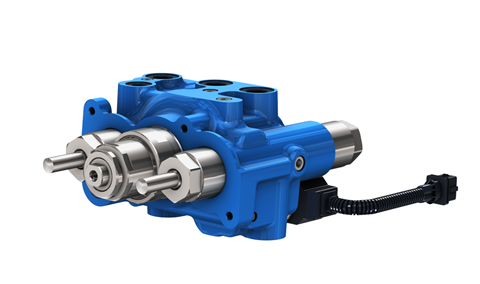

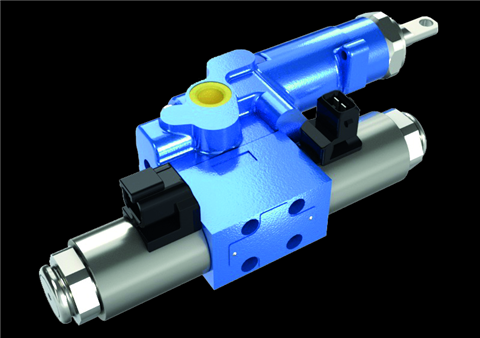

Poclain Hydraulics has renewed its electrohydraulic brake valve portfolio with products such as steering assist braking valves and park lock valves (below).

Poclain Hydraulics has renewed its electrohydraulic brake valve portfolio with products such as steering assist braking valves and park lock valves (below).

The valve also allows the machine to maintain mechanical pedal braking actuation. Simpler valve designs are also available when mandatory disengagement is not necessary, the company said. In four-wheel tractors, the valve allows for automatic disabling of front brake actuation when tractor is running in field mode or when brakes are assisting on turns, Poclain Hydraulics said.

The steering assist valves are available with flow rates up to 7.93 gpm (30 lpm), with operating

pressures to 3625 psi (250 bar) and output pressures from 290 to 1812 psi (20 to 125 bar).

Dual line braking: Electrohydraulic trailer brake valves are available in two different designs, one for single and one

for dual-line architectures. Piloted electrohydraulically, both offer proportional braking controls and cover closed and open center circuits for design flexibility, Poclain said. Dual line braking valves can also provide leakage protection to avoid oil spills, contributing to increased environmental security.

The dual line brake systems have a nominal flow rate of 18.49 gpm (70 lpm) and are EU 2015/68 compliant, the company said.

Park Lock: Poclain Hydraulics said its park lock brake valves now meet the latest EU 2015/68 regulations while anticipating potential future regulation requirements worldwide. Designed for emergency/park brake actuation, they deliver brake pressures up to 2320 psi (160 bar) with a maximum operating pressure up to 3625 psi (250 bar).

A selection of actuators available are available, enabling pulling force to customized, the company said.

In renewing its legacy electrohydraulic brake solutions, Poclain Hydraulics said it has augmented valve management possibilities with a new range of integrated or onboard electronic control units (ECU). The systems allow machine designers to meet advanced control requirements for safer system performance and improvement of overall vehicle dynamics, which can optimize energy consumption and help provide a reduced carbon footprint. The renewed valve range ensures readiness for future machine designs, Poclain Hydraulics said, as it enables OEMs to prepare to integrate additional functionalities by adjusting braking rate parameters to working conditions via software. These functionalities can include hill start; automatic braking collision detection; brake failure and wear detection; and override signals to autonomously stop the vehicle and improve vehicle safety.

Poclain’s EHB systems are built at its competence center for valves in Žiri, Slovenia, with electronic and software development maintained at the company’s headquarters in Verberie, France.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM