Read this article in Français Deutsch Italiano Português Español

Kalmar enters EV production, unveils autonomous terminal tractor

09 May 2025

Terminal tractor manufacturer Kalmar announced it has received its first orders for the Ottawa OT2 EV Electric Terminal Tractor (OT2 EV). Production of the OT2 EV, a third-generation model fully designed and built in-house, began the first week of April at the company’s Ottawa, Kan. (U.S.) facility.

Kalmar Ottawa OT2 EV Electric Terminal Tractor. (Photo: Kalmar)

Kalmar Ottawa OT2 EV Electric Terminal Tractor. (Photo: Kalmar)

The OT2 EV has a maximum GCWR of 81,000 to 195,000 lb. and offers a choice of storage capacities of 105, 140 or 210 kWh from its lithium ion batteries. The latest generation eliminates the transmission from the driveline, moving to a direct drive solution. The unit incorporates an active thermal management system as well as a DC FastCharge system for decreased charging time.

The OT2 EVhas undergone more than a year of field testing in real-world customer operations and controlled test environments. Kalmar said customers have highlighted faster charge times, improved uptime, quieter operation and significantly lower maintenance needs as key advantages over traditional diesel terminal tractors.

“We’re seeing strong customer interest in the OT2 EV, even as the regulatory landscape continues to evolve,” said Thor Brenden, president, Terminal Tractors, Kalmar. “Ports and warehouse operators are still pursuing zero-emission targets to improve air quality in their communities, and regional regulations like California’s WAIRE rule reward investments in clean technologies like our T2 EV.

“Beyond compliance, customers recognize that the terminal tractor’s duty cycle is a perfect match for electrification,” he continued, noting, “they can conveniently charge on site and benefit from quieter, healthier working environments for drivers and yard staff.”

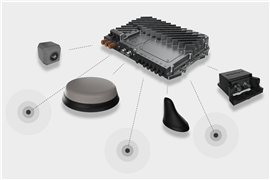

Kalmar also unveiled the Ottawa AutoTT, an autonomous terminal tractor solution resulting from a joint development agreement, signed in March 2024, with autonomous technology provider Forterra.

The joint development agreement leverages Kalmar’s terminal tractors and Forterra’s AutoDrive, an autonomous driving system built to operate in extreme environments and complex driving scenarios that meet military standards.

The Ottawa AutoTT is the result of a joint development agrement between Kalmar and Forterra. (Photo: Kalmar)

The Ottawa AutoTT is the result of a joint development agrement between Kalmar and Forterra. (Photo: Kalmar)

Kalmar has equipped the AutoTT with an automation-ready drive system, allowing it to operate safely and efficiently without a driver. Forterra’s AutoDrive system will enable the unit to perform complex autonomous maneuvers such as moving trailers in busy yards with precision.

The AutoTT is also fully integrated with Kalmar One, a scalable automation platform currently used in container terminal operations, managing fleets of up to 200 autonomous units.

Kalmar will initially roll out the AutoTT for use in distribution centers across North America. Following successful implementation, the technology will expand into container terminals and other industrial operations globally.

The AutoTT is currently undergoing its second round of testing, with plans to be in full production by late 2026. It will first be available for the diesel-powered Ottawa T2, with an electric version (T2EV) to follow.

“The Kalmar Ottawa AutoTT is a testament to our commitment to driving automation forward in the logistics industry,” Timo Alho, director, Product Management, Automation, Kalmar. “By integrating Forterra’s advanced AutoDrive platform with our proven terminal tractor technology, we are delivering a solution that enhances both safety and operational efficiency.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM