Read this article in 中文 Français Deutsch Italiano Português Español

Knorr-Bremse shows zero-emission safety-critical systems

16 September 2024

At IAA Transportation, taking place this week in Hanover, Germany, Knorr-Bremse is presenting safety-critical systems for reducing carbon, noise, oil and particulate emissions, with the aim of working with commercial vehicle customers to build emissions-free transportation.

The company will present market-ready products as well as products currently under development, including:

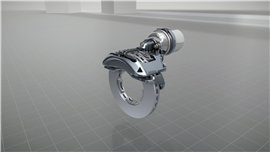

The modular SYNACT disc brake family includes axial and radial brakes. (Photo: Knorr-Bremse)

The modular SYNACT disc brake family includes axial and radial brakes. (Photo: Knorr-Bremse)

- Wheel end with SYNACT disc brakes: The modular SYNACT disc brake family features axial and radial brakes, offering lower weight, Active Caliper Release (ACR) for fuel savings and subsequent reduction in a vehicle’s carbon footprint. The Noise, Vibration and Harshness (NVH) toolbox delivers noise-optimized braking behavior in city centers.

- Electromechanical Braking System (EMBS): The EMBS offers full “brake-by-wire” capabilities. It includes a redundant electrical power supply, redundant brake control unit and electromechanical brake actuators, as well as a built-in parking brake function. Other advantages are offered in terms of installation space, noise generation and braking precision.

- Electric Power Steering (EPS): This all-electric steering system is designed to support electrification and automated driving. It applies a “power-on-demand” principle to reduce a vehicle’s energy and fuel consumption, which in turn cuts energy costs and carbon emissions. The need for no oil changes further contributes to sustainable operation.

Electric Power Steering supports electrification and automated driving in commercial vehicles. (Photo: Knorr-Bremse)

Electric Power Steering supports electrification and automated driving in commercial vehicles. (Photo: Knorr-Bremse)

- Redundant Power Management System (rPMS): This system manages the power supply for safety-critical systems including for all-electric steering systems, brake control systems and the controllers and sensors required for automated driving. Two independent power-supply circuits are designed to guarantee system availability and support the failsafe operation of highly automated commercial vehicles.

- E-compressors: A variety of electrified compression technologies are available to match to specific customer requirements. Options are available to cover the e-vehicle spectrum, from electric trucks using very little air through to articulated e-buses with very high air requirements.

- eSilencers: The eSilencer cuts noise emitted by the release of compressed air from vehicles to 68 dB(A), said Knorr-Bremse, making it suited for electrified commercial vehicles operating in noise-sensitive areas such as city centers.

- Brake Resistor System (eBRS): The liquid-cooled eBRS provides a zero-emission, sustained-action braking function in commercial vehicles, regardless of battery size or charge level, said Knorr-Bremse. The scalable, modular system is designed for seamless integration into a vehicle’s drive, thermal and energy management systems.

- Trailers: Trailer solutions like the weight-optimized NexTT disc brakes, combined with Active Caliper Release, can further contribute to sustainability efforts by saving fuel and energy, the company stated.

“Our ultimate goal is road traffic that generates no emissions at all. This green transformation is an integral part of Knorr-Bremse’s vision, and we aim to give our customers every possible support on their way to zero emissions,” said Bernd Spies, member of the executive board of Knorr-Bremse AG, with global responsibility for the Commercial Vehicle Systems division. “We have an in-depth understanding of all aspects of a zero-emission vehicle and the various fundamental changes required to vehicle architecture over the long term. And this is the starting point for our innovative technologies and solutions, which must satisfy economic and ecological criteria while being as integration-friendly as possible.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM