Read this article in French German Italian Portuguese Spanish

Cummins, Komatsu collaborate on mining hybrid solutions

16 September 2025

Cummins Inc. and Komatsu Ltd. have signed a memorandum of understanding (MOU) to collaborate on the development of hybrid powertrains for surface haulage heavy mining equipment. Komatsu has included Wabtec, its drive system supplier, as part of the collaboration.

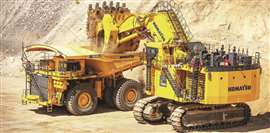

Cummins and Komatsu will develop hybrid solutions for heavy mining equipment used for surface haulage. (Photo: Komatsu)

Cummins and Komatsu will develop hybrid solutions for heavy mining equipment used for surface haulage. (Photo: Komatsu)

Cummins and Komatsu previously teamed with global mining company Vale to develop dual-fuel haul trucks, which used a mix of ethanol in diesel, to reduce CO2 emissions.

In this latest collaboration, the companies will add hybrids – designed to capture braking energy and deliver faster cycle times – to their product roadmaps of power technology solutions for progressive decarbonization in large mining haul truck applications, the announcement stated. The joint development effort is intended to leverage both companies’ global capabilities to enable the acceleration of optimized hybrids for mining, including new and retrofit solutions.

Cummins noted that its acquisition of First Mode assets in February 2025 brings critical capabilities and development pace to the efforts, with pilot units deploying yet this year.

“We have a robust team of Cummins and former First Mode experts dedicated to hybrid development and optimization,” said Gbile Adewunmi, Cummins vice president – Industrial Markets, Power Systems, “and now collaborating with Komatsu, we can bring miners the flexibility and confidence they need to decarbonize and improve total cost of operations.”

Dan Funcannon, senior vice president, Komatsu Surface Haulage Business Unit, described the collaboration as “an important step in advancing practical decarbonization solutions,” adding: “Together, we’re helping bridge current operational needs with future low-carbon goals to support our customers’ sustainability efforts.”

A key first step will be the commercialization of hybrid retrofit kits, said Molly Puga, First Mode general manager.

“With the pace of development already under way now accelerated by this collaborative partnership, we’re confident in delivering hybrid products at scale well in advance of 2030,” she stated. “The initial First Mode retrofit kit pilot will go into the market in the coming months, where we expect to see double-digit fuel savings in mining operations.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM