Read this article in Français Deutsch Italiano Português Español

ZF premieres next-gen solutions at ACT Expo

01 May 2025

ZF made two major product announcements at the 2025 Advanced Clean Transportation (ACT) Expo in Anaheim, Calif., including the North American debut of the next-generation TraXon 2 hybrid automated manual transmission (AMT), and the global premiere of the e-comp Scroll, a next-gen air compressor purpose built for electric and hybrid commercial vehicles.

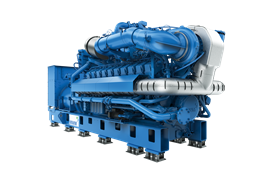

ZF TraXon 2 hybrid automated manual transmission. (Photo: Becky Schultz)

ZF TraXon 2 hybrid automated manual transmission. (Photo: Becky Schultz)

The TraXon 2 hybrid is the next evolution of the company’s modular AMT, designed to hybridize current commercial vehicle platforms with minimal effort and complexity. According to ZF, it can enable up to 14% CO2 emission reduction/fuel savings for short haul operations and up to 9% for long haul applications in hybrid electric vehicle applications. Depending on charging infrastructure density, vehicle weight and battery size, the hybrid variant is also reported to achieve up to 40% CO2 emission reduction/fuel savings in plug-in hybrid electric vehicle (PHEV) applications.

“The debut of the TraXon 2 hybrid in North America highlights ZF’s commitment to advancing cleaner mobility solutions for the commercial vehicle industry,” said John Hawkins, senior vice president of the Americas, Commercial Vehicle Solutions at ZF. “Whether it’s full electrification, hybrid systems or highly efficient ICE-based transmissions, we’re focused on delivering performance and total cost of ownership advantages across all segments.”

ZF e-comp Scroll offers an oil-free, low-noise and minimal vibration solution. (Photo: Becky Schultz)

ZF e-comp Scroll offers an oil-free, low-noise and minimal vibration solution. (Photo: Becky Schultz)

ZF also showcased the e-comp Scroll, its latest electrification technology for commercial vehicles. The air compression system is an oil-free, low-noise and minimal vibration solution for medium- and heavy-duty hybrid, battery-electric and fuel cell trucks, bus and coach applications.

The e-comp Scroll uses interlocking scrolls for air compression, reducing noise to 67 dB(A) at 250 liters per minute. This is especially beneficial for electric vehicles, which are quieter than traditional vehicles, and therefore require other components, such as an air compressor, to ensure low-noise operation, ZF stated.

Powered by an electric motor, the system can compress air up to 12.5 bar (181 psi) with variable speeds to meet different customer needs. It includes an inverter and liquid cooling to maintain temperature and further contribute to energy savings.

The e-comp Scroll uses interlocking scrolls for air compression, reducing noise to 67 dB(A) at 250 lpm. (Photo: Becky Schultz)

The e-comp Scroll uses interlocking scrolls for air compression, reducing noise to 67 dB(A) at 250 lpm. (Photo: Becky Schultz)

“The innovative design of the e-comp Scroll helps ensure efficient air compression and helps optimize total cost of ownership through low maintenance, achieved by eliminating the need for oil lubrication,” said Paweł Porczyński, head of Product Line, Chassis Solutions, ZF Commercial Vehicle Solutions. “By automatically switching off between compression cycles, the e-comp Scroll saves energy while helping to improve the overall experience for the driver, passengers and other road users alike.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM