Read this article in 中文 Français Deutsch Italiano Português Español

Continental develops new hose intended to prevent H2 fuel penetration

11 February 2025

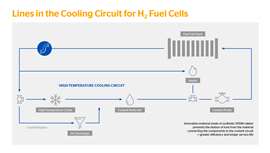

Infographic outlining cooling circuit for H2 fuel cells (Image provided by Continental)

Infographic outlining cooling circuit for H2 fuel cells (Image provided by Continental)

Continental has reported development of a new product which is said to reduce the penetration/escape of hydrogen in commercial vehicle fuel systems.

The very low density and minute size of H2, or molecular hydrogen in its fuel state, allows it to seep into and pass through many material types. This both results in the loss of H2 fuel and also damage to the containing material, in some cases know as hydrogen embrittlement.

Harald Kreidner, head of Research and Development at ContiTech business area OESL, explained: “Permeation resistance, anti-static and high pressure are challenging requirements. We are combining our material expertise so we can tailor elastomers, thermoplastics and metals for use in hydrogen powertrains.”

To combat the seepage and loss of hydrogen fuel, Continental has developed a synthetic EPDM (ethylene-propylene diene) rubber hose which incorporates a layer of thermoplastic material intended to act as a barrier. This is said to guarantee safe vehicle operation as it ‘minimizes the probability of a flammable hydrogen-air mixture occurring in the area of the hydrogen-carrying line’.

While delivering improved safety, the line is also said to improve overall vehicle range due to reduced fuel loss.

Additionally, the new hose material will allow extended service/replacement intervals, helping to reduced cost of ownership.

It will also help to prevent ions from the hose material from entering the fuel cell cooling system and possibly damaging the proton exchange membrane (PEM), which can reduce its working life.

Although the thermoplastic layer can reduce hydrogen penetrating into the hose material, the hose itself has to remain flexible. Continental noted that it has brought together its expertise in this area together in a new business division, Original Equipment Solutions (within the ContiTech group) to develop this and other solutions for the commercial vehicle sector.

Mark Klein-Hietpas, director of CV sales in the OESL business area explained: “As with combustion technology, we have also succeeded in finding the materials and material compounds that can cope with the sometimes contradictory requirements for hydrogen and battery circuits.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM