Read this article in 中文 Français Deutsch Italiano Português Español

Caterpillar applies clean sheet to new loaders – Part 1

30 October 2024

Part 1 of this two-part article looks at the new engines and advanced hydraulics that went into the company’s next-generation skid-steer and compact track loaders.

Long known for its big machines, Caterpillar is now upsizing its compact equipment line with the introduction of the 285 and 285 XE, the largest compact track loaders (CTLs) the company has ever produced. With rated operating capacities (ROCs) of 4,719 and 4,816 lb. with counterweight, lift heights of 146 in. and tilt breakout force of 13,920 lb., the models land in an all-new CTL class size for the company.

While showstoppers in themselves, the 285 and 285 XE were just two of eight models that debuted at a recent media event highlighting the company’s next-generation skid-steer loaders (SSL) and CTLs. Other additions included the 250, 260, 270 and 270 XE SSLs and 275 and 275 XE CTLs. The company also announced that the next-gen 255 and 265 CTLs, previewed in late 2023, have entered series production.

According to Caterpillar, its next-gen vertical lift loaders offer lift height increases of 2 to 8 in.; breakout force gains of between 5% to 37%; and ROC boosts of up to 21% compared to the D3 models they’re intended to replace.

Performance-matched engines

The revamped product lineup stems from a “clean sheet” approach that Jayesh Menon, new product introduction manager at Caterpillar, said included development of new Tier 4 Final/Stage V-compliant engines specifically matched to the machines.

With rated operating capacities of 4,719 and 4,816 lb. and lift heights of 146 in., the 285 and 285 XE are the largest compact track loaders Caterpillar has ever produced. (Photo: Caterpillar)

With rated operating capacities of 4,719 and 4,816 lb. and lift heights of 146 in., the 285 and 285 XE are the largest compact track loaders Caterpillar has ever produced. (Photo: Caterpillar)

“We started with a blank piece of paper, and we said, ‘Instead of us trying to fit a machine around a power plant, in this case an engine, or trying to fit an engine around a machine, what if we develop both for each other?’ And that’s really where we were able to not set any limits,” Menon said. “We were able to find the right engine solution that provided the right power and performance where you were able to also take full advantage of it from a machine design and from a hydraulic architecture perspective.

“So, it’s a balance of what the engine could deliver, what the machine design can handle and what the hydraulics can take advantage of. It’s really a fully matched, integrated solution, and starting with a clean sheet is what allowed us to do that.”

The 250 and 260 SSL and 255 CTL have a C2.8T engine rated 74 hp (55 kW) and offering 13% more torque over their predecessors; the 265 has the same engine but with 43% more torque. The 270, 275 and 285 are powered by the C3.6TA rated 111 hp (82 kW) with a 35% torque increase, while XE variants have the same engine rated 134 hp and with a 50% torque boost.

The next-gen loaders feature new performance-matched Tier 4 Final engine platforms that deliver a more aggressive torque curve for enhanced performance. (Photo: Becky Schultz)

The next-gen loaders feature new performance-matched Tier 4 Final engine platforms that deliver a more aggressive torque curve for enhanced performance. (Photo: Becky Schultz)

Both engine platforms are designed with a more “aggressive” torque curve, meaning full engine power can be applied over a wider range of engine speeds.

“Normally, a machine would start to bog down [in the pile] and that torque curve really dive – you don’t really have that usable power anymore,” said Trevor Chase, senior product consultant and new product introduction lead for Caterpillar. “We’re able to keep that torque curve going and remaining flatter so that we can continue to put power to the ground... That gives us that much more power in pushing or digging, which is really important.

“We’ve proven that, with the engineering, we can keep that torque flatter longer and have a much better, more productive experience with the machine.”

Added pressure

The hydraulic architecture of the next-gen models has also been developed to deliver more hydraulic horsepower to attachments with built-in load-sensing capabilities.

“When you are going into a pile and you are demanding more hydraulic power, that hydraulic system is able to provide that feedback to the valve, to the engine, and it is able to deliver that power when it’s needed,” said Menon.

The hydraulic architecture of the next-gen models has been developed to deliver more hydraulic horsepower to attachments. (Photo: Caterpillar)

The hydraulic architecture of the next-gen models has been developed to deliver more hydraulic horsepower to attachments. (Photo: Caterpillar)

“The other benefit of the hydraulic architecture is… we’re able to [more finely tune] the hydraulics. So, if you’re doing fine grading and you’re making those very minute adjustments, the system responds immediately. There’s no lag,” he explained. “So that’s again, matching the hydraulic architecture to be able to take full advantage of the capability of the engine and the machine design.”

The closed-center auxiliary hydraulic system in the new machines has increased standard hydraulic pressure 5% to 3,500 psi (24,130 kPa), enabling the loaders to operate all Cat Smart Attachments using standard hydraulics.

The 250, 260, 270 and 275 machines are also shipped as High Flow ready from the factory. Optional High Flow can be activated via a new software-enabled attachment (SEA) that provides on-machine or remote activation; no added hardware is required. Hydraulic flow increases to 30 gpm (113 lpm) on the 250, 260 and 270 and 34 gpm (129 lpm) on the 275 at standard system pressure.

Taking this a step further, optional High Flow XPS increases auxiliary hydraulic system pressure to 4,061 psi (28,000 kPa) at 30 gpm (113 lpm) on the 250 and 34 gpm (129 lpm) on the 260, 270, 275 and 285. For the 270 XE, 275 XE and 285 XE, High Flow XPS sees auxiliary hydraulic system pressure jump to 4,496 psi (31,000 kPa) with hydraulic flow of 40 gpm (150 lpm).

Part 2 of this article will look at the new undercarriage featured in the larger compact track loaders, as well as a new advanced technology package available on all models.

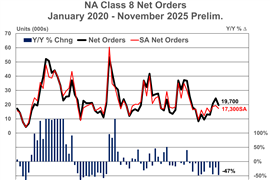

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM