Read this article in Français Deutsch Italiano Português Español

Antares provides legacy hardware support

11 January 2024

Jens Haehn is co-founder and managing partner of Antares Life Cycle Solutions. Prior to the formation of the company, Haehn was with Mann + Hummel for 18 years; the other co-founder has a similar background in engineering.

“[At Mann + Hummel] I was involved with new product development, which was great fun,” he explained in an interview with Power Progress International. “But I was also responsible for the ‘long tail’, the managing of parts for older machines. It was there that I saw how many suppliers and part manufacturers have issues with delivery of parts for older machines.”

Jens Haehn, Antares (Photo: Antares)

Jens Haehn, Antares (Photo: Antares)

After a rhetorical “Why is that?”, Haehn continued: “The active production phase for an engine or machine could be anywhere up to 15 years, but that same equipment could be in service for 40 years. After end of production (EOP), the service life could be two or three times as long as the production cycle.”

A lot can happen over that period of time. A supplier could be sold and broken up, they could carry out an internal reorganisation that changes company focus, or they could simply go out of business. Under any of these circumstances, tooling can go missing or fall into disrepair. The end result is a shortage or no spare parts. Even when an OEM still has parts in stock, Haehn said most lack the internal processes to arrange remedial work on customer machines after EOP.

“Typically, companies have a focus on innovation and new product development. When it comes to the long tail, there’s not usually the internal setup to manage those requests. But that means there are a lot of potential customers and we thought we could do better for them.”

Process strategy

The primary focus of Antares is to keep legacy equipment operational. The company can provide consulting services, but Haehn said that most work revolves around reverse engineering and supply of parts – some of which can date back to the 1960s or ‘70s.

We can source the tooling, produce the components and deliver those so the service contract can be fulfilled Jens Haehn, Antares

The work can involve machines from a wide range of industries, including construction, agriculture, marine, mining and rail; wherever there is high-value equipment, Antares can help keep that hardware operational. But the machinery has to represent a suitably high value to make the process worthwhile.

“If the cost is too high and refitting exceeds the value of the machinery, that’s where the process does not work. But while we’re not cheap, I think we’re competitive when it comes to pricing.”

Haehn added: “Look at it this way. Our customers have to resell our services to their customers, so we have to be competitive.”

Business model

While it might be assumed that Antares works directly with the engine and machine owners, that is not the case. Instead, Haehn explained that the business model involves the company playing a support role to the OEM.

“The ship builder might have produced a vessel fitted with a Wartsila engine. If there is a problem with that engine, the ship builder is obliged to carry out the maintenance work under any existing service contract. But they’re possibly not in a position to complete that work; that’s where we could come in. We can source the tooling, produce the components and deliver those so the service contract can be fulfilled.”

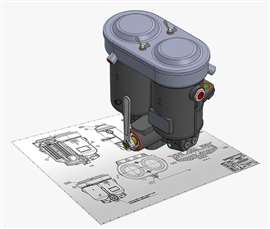

Duplex filters for marine engines (Photo: Antares)

Duplex filters for marine engines (Photo: Antares)

The first step in helping the OEM and its customers is to search for existing parts. Such is the focus on new machinery that as products are launched, parts for older machines can fall off inventories or simply end up forgotten in an unused corner of a warehouse – that is until Antares comes calling to find them.

If original parts from the OEM or Tier supplier cannot be located, Antares with then leverage its expertise to reverse engineer the components or assemblies. Those details are then forwarded to a subsidiary in India which produces castings and machined final parts, taking advantage of the lower-cost market. Haehn stated that the finished parts are identical to the original in form, fit and function.

“We had a client which needed a specific filter which had been produced by Mahle, but they had stopped making that exact item. The customer had approached a series of other filter manufacturers, but they had all declined to help. It was our challenge to produce filters to the same exact specification.”

Producing these parts involves a considerable amount of work – with very low-volume results. Haehn explained that with this model, the customer would be invoiced for the tooling and related engineering. “This is engineering as a service. With such low volumes, the per-unit part price cannot absorb the engineering costs,” he said.

Burner head for an industrial burner chamber (Photo: Antares)

Burner head for an industrial burner chamber (Photo: Antares)

3D printing

Where it’s unfeasible to produce the tooling and other elements required for production of replacement parts, Antares has looked to leverage alternative routes to finished part delivery.

“In some cases, we were not able to produce the tooling at a suitable price point, which meant looking for another production method. Instead of tooling, we scanned the part and then used 3D printing to deliver the part,” said Haehn.

Antares has been using additive or deposition printing since 2019. While the process was originally limited to polymers and plastics, later machines can work with metals – to demonstrate, Haehn showed an aluminium filter housing which had been produced using the technique.

“The parts are like-for-like, so the quality is there. The issue is that if I buy this from a foundry the cost is about €50. The cost for a 3D printed part is about €1,500. So it’s a one-for-one strategy, we won’t be using this method for any kind of volume production,” he explained with a smile.

Sustainability sells

Besides keeping older machines running in order to reduce capital expenditure, the process of keeping older equipment operational is clearly a route to better sustainability.

Reverse engineering supports part development (Photo: Antares)

Reverse engineering supports part development (Photo: Antares)

“Companies obviously want to sell new equipment,” said Haehn. “But there’s an obligation to reduce everyone’s respective carbon footprint. Remanufacturing and refurbishing of machines and engines plays favourably into the sustainability equation.”

In the end, relying on companies like Antares to maintain equipment and keep machines in service plays into extending the OEM/customer relationship. Where the OEM is seen to actively support the customer, particularly outside any defined obligation (legal or otherwise), it is likely the same customer will return to the OEM when it comes time to purchase replacement hardware.

“We work behind the scenes for the OEM,” explained Haehn. “Instead of the OEM helping customers on a case-by-case basis, we try to take a strategic, long-term view. We’re there to help the OEM support their customers. Aside from any invoicing for tooling and related work, it’s unlikely the customer would ever know we were involved.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM