Read this article in French German Italian Portuguese Spanish

ABB goes to next level to boost electric drivetrain efficiency

24 January 2024

Power Progress International spoke to ABB’s Traction division about the benefits of electric powertrains for buses

Electric powertrains produced by ABB have been incorporated into a series of trolleys, Bus Rapid Transport (BRT) systems and off-highway applications.

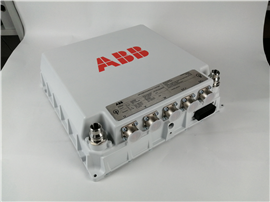

ABB HES580-3L inverter. (Photo: ABB)

ABB HES580-3L inverter. (Photo: ABB)

At Busworld 2023, held in Brussels last October, David Segbers, global product manager for eMobilty Drivetrain within ABB’s Traction division, explained that the experience gained through involvement with these projects has allowed the company to target a new market — the standard eBus segment.

To support this initiative, ABB launched the new HES580-3L inverter. The unit features a series of advanced functions including three-level topology. In addition to reducing harmonic motor losses, Segbers noted that semiconductors incorporating three-level topology can switch between plus, minus and neutral settings. This is an improvement over conventional two-level topology, which allows the inverter to only switch between plus and minus.

Segbers offered more detail: “This guarantees a smoother output wave, which reduces harmonic losses in the electric motor by up to 75%, thus increasing the efficiency of the electric drivetrain. We believe this is the first three-level inverter on the market for buses.

“We’ve made huge progress in electric drivetrain technology since Busworld was last held in 2019,” he added. He believes the new HES580-3L inverter will offer bus operators an opportunity to extend the length of journeys by providing an improved power supply for motors.

Deliveries of the HES580-3L inverter to pilot customers started in late 2023.

ABB battery systems used in mining applications are now available for electric buses. (Photo: ABB)

ABB battery systems used in mining applications are now available for electric buses. (Photo: ABB)

Cooling capability

ABB also introduced its second generation of the AMXE25OS water-cooled electric motor. “This motor weighs 20% less than our first-generation units and offers increased power and torque,” Segbers said.

The motor is available in two lengths and power ratings. First customer deliveries were set for Q1 2024.

Motors from the same family group are available for off-highway applications, with a choice of four frame sizes and power output from 20 to 500 kW.

Battery power

ABB’s electric bus drivetrains feature the company’s own battery packs. These use a lithium-titanium-oxide cell technology.

“The key performance indicator of this chemistry is not energy density but power density, which is ideal for applications that discharge and recharge rapidly, such as trolley buses,” said Segbers. “We are looking at 240-kW packs with ultra-fast charging at charging stops and a lifespan of 20,000 charging cycles or more.”

Besides buses, typical applications for ABB batteries include mining trucks and crawler cranes. In the off-highway market, ABB also offers line converters for grid connections; application examples include excavators connected to a power cable or underground mining machines.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM