Read this article in Français Deutsch Italiano Português Español

Fetis Group shows hydrogen-based solutions at Hyvolution

29 January 2025

At the HYVOLUTION exhibition, January 28-30, in Paris, low-carbon solutions integrator Fetis Group is showcasing a hydrogen-powered hybrid generator set, successful implementations of a marine hydrogen power system as well as a scalable, transportable hydrogen production solution.

Fetis Group hydrogen generator. (Photo: Fetis Group)

Fetis Group hydrogen generator. (Photo: Fetis Group)

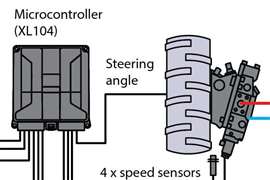

The new gen-set range is based on an internal combustion engine specially designed to run on all types of hydrogen, including white hydrogen. The range is comprised of two solutions. The H150-ICE hybrid unit, which incorporates a battery pack, optimizes energy management and meets high-dynamic requirements. It has a rated output of 150 kVA and a maximum output of 195 kVA. The H100-ICE unit can be synchronized and combined with a battery pack according to customer requirements. Its rated power is 100 kVA.

Compared to traditional diesel generators, the company said the gen-set range offers a 70% reduction in carbon emissions plus low-noise operation due to quieter combustion technology and hybrid operation.

The range is intended to replace diesel generators for events and rental applications, as well as for renewable energy installations. The gen-set can be used when the carbon footprint and/or exhaust emissions are an issue, said Fetis Group, or to convert waste hydrogen produced as a byproduct from industrial processes into electricity that can be fed back into the grid.

Ocean Eco 90 application

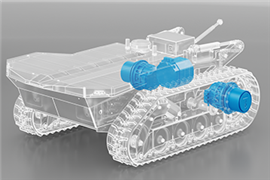

The Fetis Group is also highlighting the power solution behind the Ocean Eco 90 project during Hyvolution. This fully decarbonized luxury catamaran combines electric propulsion and hybridization to deliver optimal performance with extended range and minimal CO2 emissions.

The Ocean Eco 90 features an electric and hybrid propulsion powered by hydrogen. (Photo: Fetis Group)

The Ocean Eco 90 features an electric and hybrid propulsion powered by hydrogen. (Photo: Fetis Group)

The Ocean Eco 90 incorporates a hydrogen-powered electric and hybrid propulsion, hydrogen fuel cell range extender (REX H2) and onboard tanks capable of storing 200 kg of hydrogen at 350 bar. The vessel also includes 200 sq. meters of solar panels generating 60 kWh, as well as high-capacity batteries. Propulsion is via Oceanwings wing sails.

In electric mode, the Ocean Eco 90 operates with zero CO2 emissions, helping to preserve marine ecosystems. With 500-kWh electric propulsion, the vessel can achieve an extended range of over 300 hours due to the combination of renewable energy systems.

Hydrogen production solution

Also at the event, Fetis Group and Aich2-imaGEN unveiled the MH-60, a hydrogen technology that provides an end-to-end solution designed to store hydrogen as a solid and generate hydrogen gas directly at the point of use.

The MH-60 provides a pure hydrogen supply suited for powering hydrogen combustion engines or fuel cells. Its solid-state design eliminates the need for gaseous or cryogenic hydrogen, Fetis Group explained, ensuring safe and convenient transport without requiring specialized equipment or handling. This simplifies permitting processes and enhances usability across diverse

Fetis Group and Aich2-imaGEN unveiled the MH-60, a hydrogen technology designed as an end-to-end solid hydrogen solution. (Photo: Fetis Group)

Fetis Group and Aich2-imaGEN unveiled the MH-60, a hydrogen technology designed as an end-to-end solid hydrogen solution. (Photo: Fetis Group)

environments.

The compact, lightweight solution delivers optimized gravimetric and volumetric energy density capable of storing 6 kg of hydrogen in a portable unit. The MH-60’s modular design allows users to link multiple units for increased capacity or higher flow rates, offering scalability.

Quick activation means hydrogen production can begin in seconds, Fetis Group said. Production is managed via an intuitive touch-based graphic user interface. Users can monitor real-time data such as hydrogen availability (mass and percentage), system pressure and the operational status of connected units.

Individual unit data, including pressure, temperature, drive percentage and remaining hydrogen capacity, is accessible via the interface. System variables like pressure set points and manual drive percentages are adjustable directly from the main screen.

Users can modify settings such as display units and screen brightness through an intuitive menu. Automation support is available via the Modbus protocol.

Pre-production orders for the MH-60 are now being accepted.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM