Volvo High Lift loader suited for log handling

11 July 2022

The L200H High Lift has a maximum lifting capacity of 24600 lb. and can stack logs to almost 23 ft. high. (Photo: Volvo Construction Equipment)

The L200H High Lift has a maximum lifting capacity of 24600 lb. and can stack logs to almost 23 ft. high. (Photo: Volvo Construction Equipment)

Volvo Construction Equipment (Volvo CE) has built upon its L180H High Lift wheel loader design to create the L200H High Lift, featuring a 27% increase in lifting capacity and a 13% larger grapple than the model it replaces. Combined with a stronger base unit, this means the new machine is capable of handling more timber per hour.

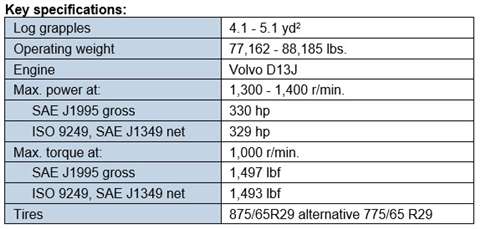

The unit ranges in operating weight from 77162 to 88185 lbs. and can be used with log grapples from 4.1 to 5.1 cu. yd. Power is supplied by a Volvo D13J diesel engine rated 330 gross hp (SAE J1995) at 1300 to 1400 rpm and with max torque of 1497 lbf. (gross) at 1000 rpm.

A new loading unit includes a reinforced lift arm system, crossbeam and rotator unit that increase the machine’s maximum lifting capacity from 19401 lb. on the L180H High Lift to 24600 lb. on the L200H High Lift. The new model is capable of stacking logs to almost 23 ft. high. Its maintenance-free rotator unit with integrated dampening system provides 360º rotation and tilt ability to easily maneuver logs in and out of piles.

Gear shifting has been optimized to suit the increased workloads, resulting in fast acceleration and smooth operation, Volvo CE states. Technologies such as OptiShift integrate the Reverse-By-Braking function and torque converter with lock-up for enhanced fuel efficiency.

The L200H High Lift is compatible with Load Assist, Volvo’s suite of apps accessible via the in-cab Co-Pilot display. The On-Board Weighing app provides real-time insights into grapple payload to help eliminate overloading, underloading, reweighing and wait times. The Operator Coaching Advanced app provides real-time information and guidance to help operators use the loader to its full potential. A tire pressure monitoring system provides the ability to check the pressure and temperature of air-inflated and hydro-inflated tires from the cab.

Other features of the new model include:

- A spacious cab with ergonomic layout, enhanced visibility, choice of seats and multi-function lever.

- Optional Comfort Drive Control to steer the machine using a lever instead of the steering wheel.

- Optional front-view camera for additional visibility at the front of the machine and on top of the stack, with the view displayed on a dedicated in-cab monitor.

- Cab tilt to 30º or 70º and an electronically operated engine hood to enable easy service access.

- External axle oil cooling system that reduces the temperature of the axles, which in turn increases axle and brake life.

- Larger 875-type low-profile L4 tires as standard

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM