Read this article in 中文 Français Deutsch Italiano Português Español

Zircotec coating supports use of lightweight materials in battery packs

03 September 2025

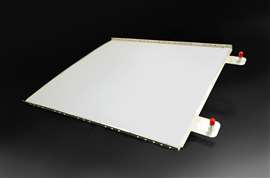

Zircotec cooling plate with ElectroHold coating (Photo: Zircotec)

Zircotec cooling plate with ElectroHold coating (Photo: Zircotec)

Zircotec, a UK-based thermal management specialist, has revealed details of a proprietary ceramic coating which will allow lighter materials other than steel to be used as enclosures and cooling plates for battery packs.

Referred to as ‘ElectroHold’, the coating combines di-electric and flameproof properties which address thermal management and electrical insulation challenges.

As such, the new product could open up the possibility of using aluminium or plastic composite materials in battery packs, helping to save weight and improve overall vehicle range.

In addition, the coating will help improve cooling plate efficiency through improved insulation and thermal conductivity. The coating should also help improve battery pack design flexibility.

“We’ve used our thermal management expertise to develop multifunctional coatings that address the new challenges of electrification,” said Dominic Graham, Zircotec Engineering director, explained.

“They provide outstanding protection against heat and flame, ensure greater electrical insulation needed for safety, and improve thermal transfer. That’s a combination that has the potential to transform the EV industry by unlocking the use of lightweight materials across battery boxes and cooling plates.”

Zircotec’s new coatings have undergone ‘rigorous’ electrical, thermal and durability testing to simulate the demands on battery packs. This included a simulated UL2596 Method A thermal runaway test event where the battery module was pushed to failure, replicating the most severe safety scenario.

The coated carbon fibre enclosure passed the test, maintaining its structural integrity to prevent flame egress and still provide electrical insulation.

Additional tests showed that the coating delivered a four-fold increase in di-electric strength over previous solutions. The coatings also proved to be resistant to mechanical stress, corrosion, chemical attack and wide-ranging temperature fluctuations.

Terry Graham, CEO at Zircotec, said: “This technology is now ready for OEMs to integrate into their production programmes and we’re proud that it’s been UK material science, coating and engineering expertise and collaborations that have led us to this transformative position.”

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM