Read this article in Français Deutsch Italiano Português Español

Allison Transmission: Axle ratio change delivers savings

11 August 2025

Experts from Allision Transmission describe how a change in axle ratio has delivered big savings for a refuse vehicle operator in the UK

Refuse vehicles operating in the UK do not require axle ratio intended for steep gradients (Photo: Allison)

Refuse vehicles operating in the UK do not require axle ratio intended for steep gradients (Photo: Allison)

Allison Transmission is a leading developer and manufacturer of propulsion solutions for commercial and defence sector vehicles. Headquartered in Indianapolis, Indiana, the company has locations in more than 150 countries around the world, including regional centres in the Netherlands, China and Brazil.

Since 1915, Allison has introduced a series of products which gone on to become the benchmark for powertrains around the world. In 1947 the company shipped the first V-drive transmissions to the Truck and Coach division of General Motors. With notable improvements over the years that included the two-speed input splitter (1955) and hydraulic and direct clutches (1958), production the transmission series continued through to 1976.

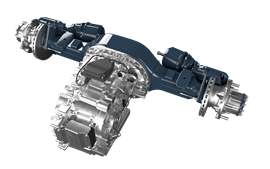

More recent introductions have included the eGen Power electric axle. Launched in 2020, the first eGen Power 100 has since been joined by the 100S single-motor and 130D variants (2021), the 130S (2022) and the 85S, which was unveiled at Busworld Europe in 2023.

eGen Power 85S electric axle (Photo: Allison)

eGen Power 85S electric axle (Photo: Allison)

Axle ratio

While noteworthy in their own right, the above examples serve to highlight the culture of continuous development at Allison; this is not a company to ‘fire and forget’ products post launch.

Case in point, while Allison has been delivering components to Mercedes-Benz for production of its Econic refuse collection trucks since 2009, the models now used in the UK have had the previously standard 6.84:1 ratio axle replaced by a 6.0:1 version.

Power Progress International spoke with Nathan Wilson, UK Market and Area sales manager and Ashley Brooks, managing director of Sales for Europe and South Africa to find out what motivated the change in axle ratio specification.

“I’ve always been familiar with axle ratios, what was required for vehicles dependent on their application,” said Wilson. “For example, motorways generally have no more than a four to 6% gradient, which means trucks don’t need a very high ratio. I realised that the Econic vehicles purchased by [refuse vehicle operator] Biffa had an axle ratio of 6.84:1 and I believed we could review this to improve economy while maintaining performance for the gradients vehicles would encounter in the UK.”

Nathan Wilson, Allison Transmission

Nathan Wilson, Allison Transmission

Following on from this, Wilson, with the assistance of Allison’s Customer Integration team, performed a simulation exercise on Allison’s iSCAAN (Internet System for Computerised Application Analysis) software. This system can configure an optimised powertrain solution for virtually any vehicle type based on an analysis of powertrain criteria such as horsepower, engine speed, vehicle weight, gradient, etc.

“You can change the axle ratio in iSCAAN, but then you do need some technical skill to understand which other components to select and why one is more suitable than another,” explains Brooks. “In this instance, it’s critical that the engineer can interpret how gearing impacts engine speed and how that can impact vehicle gradability.”

Wilson then checked with Mercedes-Benz and found the OEM had a range of available axle ratio choices. Based on results from the iSCAAN system and the options offered by Mercedes-Benz, he found that the best choice for refuse collection vehicles operating in the UK would be a 6.0:1 ratio, taking into consideration the terrain and normal use-case scenarios.

New Biffa trucks use 6.0:1 axle ratio (Photo: Biffa/Allison)

New Biffa trucks use 6.0:1 axle ratio (Photo: Biffa/Allison)

Wilson went on to present his findings to management teams from Mercedes-Benz UK and Biffa. Having spent 16 years with Mercedes-Benz and working with Biffa on behalf of Allison for nine years, Wilson was in an ideal position to state his case for using the different axle ratio.

“Mercedes already had the ratio available, so from there I recommended that Biffa specify the 6.0:1 axle ratio on its new refuse trucks,” said Wilson.

Great results

Wilson recounts that Biffa first ordered 10 trucks with the new axle ratio. More orders were received and now the company has about 100 Econic models which use the 6.0:1 gear ratio. In total, the trucks have covered more than 700,000 miles (around 1 million kilometres) collecting trade and domestic waste across the UK.

“The 6.84:1 axle ratio is for gradients up to 35%,” says Wilson. “There’s virtually no where in the UK where the trucks would encounter that type of slope, even at a refuse collection centre. They only need to have gradability up to about 25%, which the 6.0:1 ratio serves very well.”

Ashley Brooks, Allison Transmission

Ashley Brooks, Allison Transmission

There are other benefits, too. Replacing the higher ratio with a lower option has resulted in a 2.4% reduction in fuel consumption. This equates to a cost saving of about £0.02/mile, or £14,000 ($18,400 approx.) per year over the current fleet.

Along with that, there are related reductions in vehicle emissions. “I recognised from the iSCAAN data that there would be a related reduction in engine speed,” explains Wilson. “Every 100 rpm reduction in engine speed equates to around a 1% saving in fuel consumption,” continues Brooks. “This lowers CO2 and NOx, while reducing cab noise and improving driver comfort.”

As part of the study, Wilson also analysed road speeds across a series of ranges. He found that even with the 6.0:1 axle, the performance would remain exactly the same.

Balanced performance returns power and savings

Allision 3000 Series transmission (Photo: Allison)

Allision 3000 Series transmission (Photo: Allison)

In the Mercedes-Benz Econic refuse collection vehicles, the 6.0:1 axle is paired with the Allision 3000 Series transmission which features Continuous Power Technology (CPT).

Wilson explains that unlike a traditional automated manual transmission which uses a synchromesh clutch system, transmissions from Allison use a set of planetary gears which are in constant contact with both the rotating and stationary clutches. This delivers a smooth application of power without any pause or judder, important for a vehicle that spends its working life stopping and starting.

This is further combined with Allison’s FuelSense 2.0 software, which provides an infinitely variable combination of shift points instead of fixed points on a shift table. Using a learning algorithm, the system can find an ideal balance between fuel economy and performance.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM