Read this article in Français Deutsch Italiano Português Español

HeavyTech wants to grind off the Rust Belt

25 June 2025

OEM startup plans to evolve off-highway equipment, manufacturing from Northeast Indiana.

Before launching HeavyTech, Mike Terzo has been working on three compact machines for agricultural, landscaping and construction applications, including this compact track loader. (Illustration: HeavyTech)

Before launching HeavyTech, Mike Terzo has been working on three compact machines for agricultural, landscaping and construction applications, including this compact track loader. (Illustration: HeavyTech)

These days, Nicholas Darrah has two business cards and both roles share the same goals – to create a technology cluster in northeast Indiana and place the region back on the map when it comes to manufacturing machinery.

As vice president of Partnerships & Government Relations for Northeast Indiana Regional Partnership (NEI), a public-private regional economic development organization, he’s part of a team that works to attract a wide range of businesses to eleven Indiana counties. As co-founder and board member of HeavyTech Inc., Darrah helps set the course of a start-up that plans to manufacture battery-electric and hybrid compact construction equipment in Fort Wayne, Ind., a city with a metropolitan population of about 500,000.

Fort Wayne, Ind.’s Electric Works, an adaptive reuse project that has transformed a 39-acre campus abandoned in 2015, was called a “game changer” by the Northeast Indiana Regional Partnership. (Photo: Chad Elmore)

Fort Wayne, Ind.’s Electric Works, an adaptive reuse project that has transformed a 39-acre campus abandoned in 2015, was called a “game changer” by the Northeast Indiana Regional Partnership. (Photo: Chad Elmore)

The view from here

“When I give a tour of NEI’s office space, I always end it in our [ninth floor] conference room where I can point to things that didn’t exist in downtown Fort Wayne when I started here seven years ago and that we had a role in,” said Darrah. “We have a lot of really cool things happening in Northeast Indiana in general, but I am very excited about HeavyTech and what it can mean to this area and the markets it will reach. HeavyTech is going to be something that, 20 years from now, I can tell my grandkids that was I was part of, and it will be putting food on the table for generations of families.”

Each machine will share as much of the architecture and components as possible, said HeavyTech. A compact wheel loader is shown in this rendering. (Illustration: HeavyTech)

Each machine will share as much of the architecture and components as possible, said HeavyTech. A compact wheel loader is shown in this rendering. (Illustration: HeavyTech)

The formation of HeavyTech was announced in May. As an original equipment manufacturer (OEM), its first products will be compact track loaders, mini excavators and small articulated loaders designed and built in-house. The machines will have a modular design that allows the end-user to switch quickly between lithium battery technology and diesel hybrid.

“We have really looked at how we design and develop these pieces of equipment, and we want to launch HeavyTech in a way that is very industry collaborative,” said Mike Terzo, co-founder and CEO of HeavyTech. “The whole industry really needs to understand how to develop and integrate this technology on the electric and hybrid front, and that’s part of what we’re doing with HeavyTech. We’re launching this company and will prove the products in front of the entire industry. We want everybody to share this experience and see what we’re doing because, ultimately, a rising tide lifts all boats in the off-highway industry.”

An entrepreneur and engineer, the off-highway equipment market got to know Mike Terzo when he launched Terzo Power Systems. The Sacramento, Calif.-based company’s HydraPulse electric hydraulic technology used intelligence to combat energy loss in fluid power systems. He moved his family to the Fort Wayne area after selling the company in 2022 and has been working on the design of HeavyTech’s machines ever since.

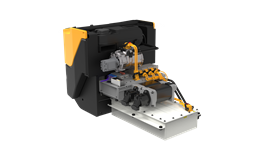

HeavyTech’s machines will be designed so the powerplant can be swapped quickly, between a lithium-ion battery pack to a hybrid. The former is shown here in a rendering created from a SolidWorks design. (Illustration: HeavyTech)

HeavyTech’s machines will be designed so the powerplant can be swapped quickly, between a lithium-ion battery pack to a hybrid. The former is shown here in a rendering created from a SolidWorks design. (Illustration: HeavyTech)

“Behind the scenes I have been building the systems and seeing what the technology can do,” said Terzo. “When we get into electro-hydraulic power-on-demand technology it’s very powerful. We only spin the pump when you’re doing a work function, and then we control the pump with an electric motor. That’s our core powertrain technology, and I’ve been working on it for almost 15 years. We’re very excited to show it to the industry.”

The company will also use proven components from outside suppliers. “There is a lot of very powerful technology out there now that we get to utilize in our machines and we’re developing a lot of the software and firmware in-house,” said Terzo. “One good thing about launching now is that in the past 10 years of the EV industry a lot of good components have been developed. There are a lot of ingredients to build advanced powertrains for heavy equipment.”

Raising money

The company is in a funding round set up through the U.S. Securities and Exchange Commission (SEC). Called Regulation Crowdfunding, Terzo said it allows the six cofounders to talk about the work they are doing to launch a new company while at the same time talk with investors. Officially introduced on May 7, HeavyTech has already raised enough to start building the chassis and ordering components for their first prototypes.

“We know we have to show the technology,” said Terzo. “We have to demonstrate it and invite as many people as possible to come here and operate these machines and see what we’re talking about. Behind the scenes, I’ve already done a lot of the proof-of-concept work, but that doesn’t help when it comes to showing it to the industry. Our first big milestone will be the vehicle demonstrations and that work be funded by equity crowdfunding.

“What we’re doing here is multifaceted,” said Terzo. “This is not just an OEM startup like we’ve already seen in the EV space. This is also an economic development. It’s moving technology forward from an industry standpoint, which I think is extremely important. It’s not a traditional OEM and we’re starting in a completely non-traditional way. I think the traditional way of getting funding has stifled innovation. The way they finance startups and technology is almost set up to not allow innovation to happen. It’s considered risk. Financial institutions don’t want risk. The hardest thing about raising startup money is because when you can’t talk about it you’re limited to very small circles of investors.”

HeavyTech’s cofounders believe that the third phase of work planned for Electric Works in Fort Wayne, Ind., could create the ideal home for HeavyTech manufacturing. (Photo: Chad Elmore)

HeavyTech’s cofounders believe that the third phase of work planned for Electric Works in Fort Wayne, Ind., could create the ideal home for HeavyTech manufacturing. (Photo: Chad Elmore)

Touring the Fort Wayne Electric Works

While much of the work behind HeavyTech has been completed from home offices and garages, the cofounders are looking ahead to how and where the machines will be assembled in Fort Wayne.

Standing at the window in NEI’s conference room, Darrah pointed to what they consider the perfect solution: tall brick buildings southwest of downtown highlight a 39-acre campus that once kept 30% of Fort Wayne’s workforce busy and supported generations of families for more than a century. General Electric abandoned the campus in 2015.

Now a mixed-use district known as Electric Works, it was considered one of the largest office projects in the United States when it opened in late 2022. The first phase of the redevelopment and adaptive reuse work included $300 million for 730,000 sq. ft. of floor space for offices, education, retail and other applications. Electric Works was added to the National Register of Historic Places in 2023.

NEI has called Electric Works a “true game changer” for Fort Wayne and the region.

The district’s developer is RTM Ventures’ Ancora, which recently reported that more than 900 people go there for work (including corporate offices of the Do It Best hardware store chain) or school (Amp Lab is a STEAM — science, technology, engineering, arts, and mathematics — high school). The West Campus, which was completed first, is projected to support more than 2,200 daily workers at full occupancy. Today, 300 apartments are under construction.

The third phase will include an Indiana Tech advanced manufacturing and engineering center on the facility’s East Campus, which Terzo said could be the ideal home for HeavyTech’s headquarters and construction equipment assembly line.

“Electric Works is a cornerstone project that is part of the story of Northeast Indiana, and for a long time it was just these derelict empty buildings,” said Darrah. “Today it’s part of the story of the revitalization of Midwest manufacturing and innovation. And I think that fits really well within our origin story.”

HeavyTech’s founders want to build two to three prototypes over the next couple of months and have working prototypes by the end of 2025.

Davide De Silvio and Mike Terzo stand on a mezzanine inside Electric Works in Fort Wayne, Ind. (Photo: HeavyTech)

Davide De Silvio and Mike Terzo stand on a mezzanine inside Electric Works in Fort Wayne, Ind. (Photo: HeavyTech)

From Indiana to the world

Thanks to cofounder and Chief Commercial Officer Davide De Silvio, whose resume includes Liebherr Group’s large engine business and FPT Industrial’s ePowertrain business, HeavyTech already has an international office.

Based in Italy, De Silvio said the “model is replicable in Europe, so from day one we have an international mentality. Our core is the resurgence of the Fort Wayne Rust Belt, and that is very important to all of us. There is a strong work ethic and a down-to-earth approach to doing business there, and that is very similar to Northern Italy. Our technology will also get a lot of traction in Europe. Offering a mix between hybridization and electrification is very appealing, and I can see HeavyTech marketing not only the machines but the powertrain itself.”

A Rivian-built delivery van makes deliveries in the West Campus of Electric Works in June 2025, a mixed-use district that opened in 2022. HeavyTech has eyed the campus as its future base of operations. (Photo: Chad Elmore)

A Rivian-built delivery van makes deliveries in the West Campus of Electric Works in June 2025, a mixed-use district that opened in 2022. HeavyTech has eyed the campus as its future base of operations. (Photo: Chad Elmore)

A question every company founder gets asked at least once is, “Why now?”

“Personally, I’m calling this my YOLO [you only live once] run,” said Terzo. “We have to try something really ambitious in our industry, and I think the time is right — strangely enough. The cooling of the EV market is helping the story. People are sold on the benefits of electric off-highway equipment, and now they want real business models. They want real metrics around what you’re selling — and it would be bad if we were trying to capitalize on the institutional investment market right now.”

“We think the timing is great right now, too, because the ‘Made in America’ mindset has teeth to it again,” said Darrah. “We’re working to start original manufacturing in the United States with technology developed in the United States. Our primary competitor outside of this space is China, and they’re not going to stop developing this technology. Someone’s got to do it, and if the traditional OEMs are not, because they don’t have the risk tolerance or incentive to do, we’ve got the ball rolling here in Fort Wayne.

“As new as HeavyTech is, it’s already interwoven into the fabric of Northeast Indiana. Everybody’s been very supportive, whether they’re actual investors or they want to be partners and are just saying, ‘how do we help?’ And ‘What can we do?’ There are a lot of different pieces that are making this work. It’s been validating to have people in the construction industry and in manufacturing understand what we’re working on and say, ‘Yes, this needs to happen.’”

At one time 30% of Fort Wayne, Ind.’s workforce worked for General Electric. The campus has been revitalized as Electric Works. (Photo: Chad Elmore)

At one time 30% of Fort Wayne, Ind.’s workforce worked for General Electric. The campus has been revitalized as Electric Works. (Photo: Chad Elmore)

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM